Prysmian's 4.0 Elevator is taking vertical mobility industry to the top floor

From Industria Italiana

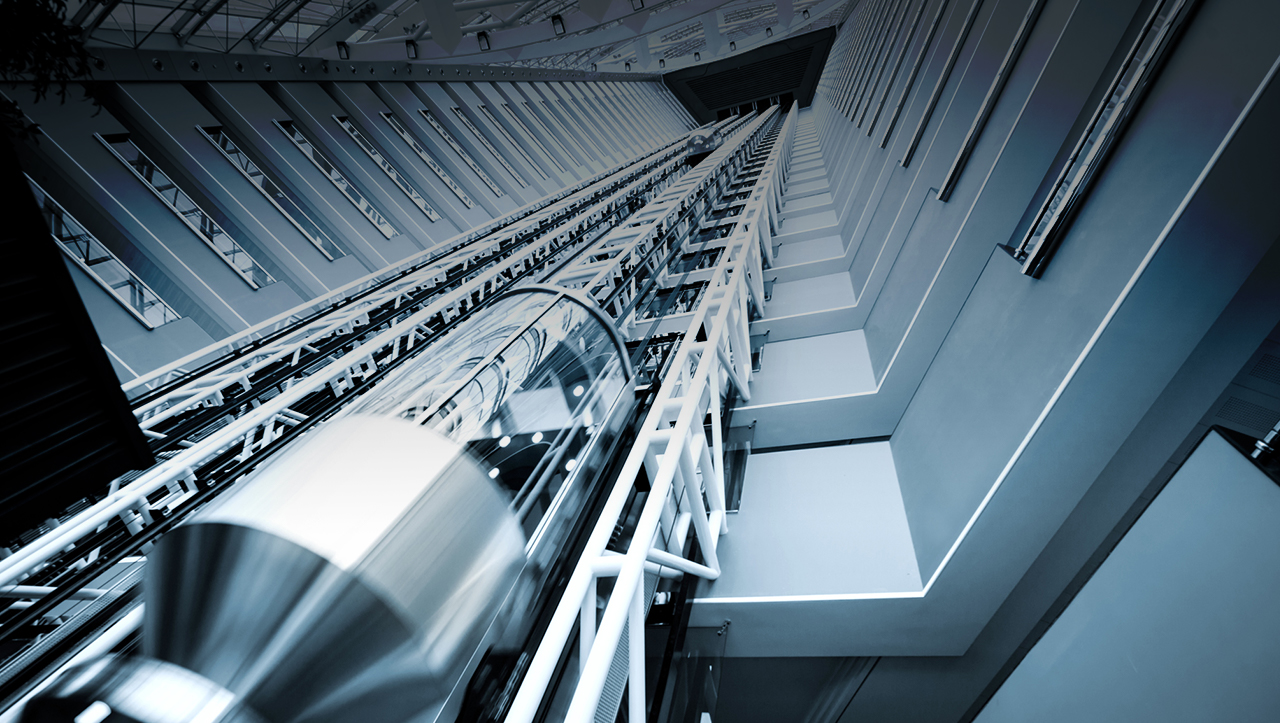

It is the most used mode of transport, and Italy is the number-two country in the world by number of units installed. Yet most of them are old. This is where innovation in the vertical mobility industry can benefit from new technologies with a focus on safety and efficiency: the IoT, AI, big data, advanced analytics and machine learning. How? Ludek Karasek, EMEA Sales Director, Prysmian Group's Elevator BU, explains.

“The average age of Europe's elevators is very high. This creates a series of problems relating above all to user safety. New technologies, the IoT, artificial intelligence and predictive maintenance can contribute to solving these problems. Italy is among the most important markets since its urban development has given rise to buildings often reaching significant heights and thus requiring elevators. Prysmian's Elevator Business Unit is responsible for producing and marketing cables and components for the vertical mobility industry. In addition, with reference to safety, our priority remains developing cutting-edge solutions that contribute to ensuring more efficient and effective elevator management."

Ludek Karasek explains in an exclusive interview with Italian magazine Industria Italiana the most important issues in the elevator industry, a segment that is undergoing a profound transformation due to technological innovation. This industry is experiencing growth after years of crisis. As a result, an event dedicated to this issue — the E2 Forum — was held in Milan last October.

Prysmian's Elevator Division

Draka Elevator Products is an integrated business unit of the Prysmian Group and a leading cable manufacturer and component distributor for the vertical mobility industry. Ludek Karasek heads up the BU in the EMEA region. The cables manufactured by Draka Elevator are currently installed in some of the world's tallest and most iconic skyscrapers, ensuring speed and safety. Draka Elevator operates through production facilities and distribution centres strategically located from a geographical standpoint in support of OEMs, independent contractors and elevator installers.

Italy going up and down

With nearly one million elevators installed, Italy has Europe's largest elevator fleet, second only to China at the global level. The units in use in Italy account for over 16% of European elevators and nearly 10% of the current global fleet, making nearly one hundred million runs daily. The elevator is for all intents and purposes the world's most used mode of transport: in Italy the average person uses an elevator 1,500 times a year. In economic terms, the elevators and escalators segment can certainly be counted among Italy's greatest industrial successes, with combined revenues of over €2.4 billion in 2017, of which 42% on foreign markets, with an over 10% share of the international market.

In recent years, the Italian elevators and escalators industry has suffered due to the challenging macroeconomic scenario. In particular, the industry's evolution has been held back by declining domestic demand as a result of the persistent weakness of investments in the construction market. The difficult domestic market situation has given rise to increasing internationalisation strategies, which have allowed the Italian industry to consolidate its position as the number-two exporter of technologies overall, following China. It is above all in the Elevator and Escalator Components industry that Italy continues to show its leadership, ranking as the number-one exporter in the world with a nearly 15% share of the global market.

Nearly 20% of Italian elevators are in service in the Lombardy region alone, which thus can boast an elevator fleet equivalent to that of all of Switzerland and slightly smaller than that of the United Kingdom. While most Chinese elevators were installed very recently, the Old Continent has one of the oldest elevator fleets. More than 30% of the elevators operating in Italy are over 40 years old and at least 50% were installed in the previous century and are not equipped with the modern technologies that ensure a higher level of user safety. "Historically speaking," Karasek explained, "Italy is a country whose urban areas include many apartment buildings of three to eight stories in which elevators are necessary to reach the units. The number of single-family homes is very small, and they are mainly located in areas outside urban centres. In Italy, the elevator is regarded as a part of the culture and essential to quality-of-life standards, which is why there are so many."

Europe

Europe has the world's oldest elevator fleet, which means that maintenance and user safety are issues of great importance to the industry. In addition, old elevators are associated with three types of problems. “First of all," Karasek continued, "is exiting the elevator: if the cabin is not perfectly level with the floor, there is the risk of tripping and falling. The second problem has to do with the doors, which do not always have photoelectric safety sensors. This means that during the closing procedure the doors may strike passengers. Finally, there is a lack of interconnection between the various devices: it therefore is not always possible to communicate with the outside world in the event of a breakdown."

New technologies

New technologies aim to offer a series of solutions that will transform the way those responsible for elevator management and maintenance do their jobs. These technologies will also ensure greater efficiency. For example, in commercial buildings, study is being devoted to ways of improving the quality of service provided, such as in the case of the Unicredit Tower in Milan: when employees use their badges to enter the bank's new office building, a display tells them which elevator to take. In addition, the elevator in question has already memorised the floor to which the employee is headed, without any need to hit the traditional button.

"The Industrial Internet of Things," Karasek explained to us, "and artificial intelligence are already having an impact on the elevator industry. These technologies will change the way in which service companies operate and will revolutionise the current business models. Companies capable of adapting may compete with OEMs that will integrate IoT strategies into their products. We believe that both the IoT and monitoring applied to the elevator industry are ways of transforming business through big data, advanced analytics and machine learning. This is the upcoming evolution in terms of the products and services that Draka Elevator will bring to the market."

Predictive maintenance

Big data and analytics, along with the IoT, now make it possible to plan targeted maintenance work, and above all before possible equipment failure that could compromise unit functionality. This approach, already adopted in the manufacturing sector, is now also being tested in the elevator industry. According to the initial results, once fully operational, the system allows a 20-25% decline in the failure rate in the medium term. Of course, the costs are also lower, because ordinary maintenance costs much less than inoperative units. One real-world example is the Louis Vuitton store in Paris: the French company has calculated that elevator downtime (the store occupies two floors) may cost up to €500 of lost sales an hour because the brand's customers are not willing to walk up the stairs.

"Predictive maintenance," Karasek added, "makes it possible to monitor operating conditions and identify possible failures in advance. Service companies can thus better plan their maintenance operations and optimise their resources accordingly. The adoption of new business models based on use time or guaranteed availability may represent a further improvement. The next step beyond predictive maintenance is prescriptive maintenance, which foresees all possible scenarios and allows companies to be prepared to face all potential events".

Safety

Directly connected to predictive maintenance is safety, which benefits considerably from the introduction of new technologies. "Safety," Karasek concluded, "has always been the main driver for the elevator industry. We are now bound for a new frontier, represented by the digital world in which elevators use artificial intelligence to 'learn’ the best way to correctly allocate stoppage for maintenance and replacement of parts. This will lead us to take a completely different approach, which will allow us to avoid all machine downtime through the contribution of the IoT. However, in order to make this scenario possible, sensors that permit more efficient monitoring will need to be adopted. Yet a greater number of sensors, like the IoT, require the entire industry to adopt effective safety systems. This is because it is certainly not a big problem if a single person's computer is infected in a café. Yet what happens if the hacking attacks focus on public safety? According to McKinsey & Company, by 2020 there will be 20 million devices connected to the Internet: ensuring safety remains an absolute priority."