Prysmian: challenges and best practices in reporting sustainability data

Alessandro Pirri, Prysmian’s Senior Manager Sustainability for Business, discusses Prysmian’s activities in sustainability reporting

Today, sustainability reporting requires a comprehensive approach, which may demand adjustments to corporate governance, investments in new systems and expertise, and ongoing commitment to sustainability principles. Which steps is Prysmian taking? Which best practices and smart approaches can the company share?

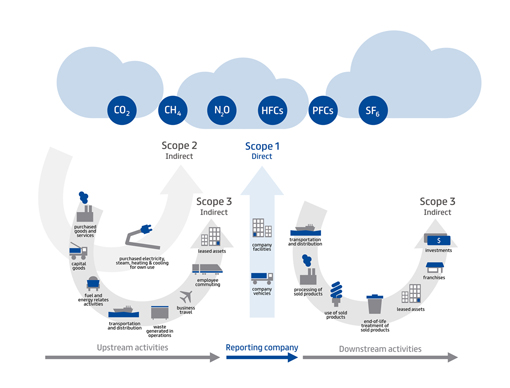

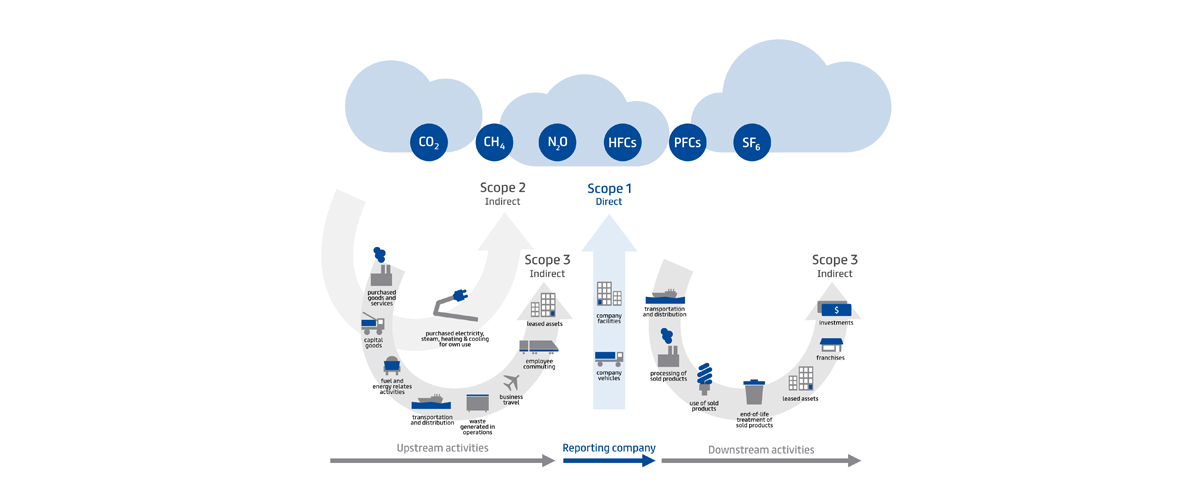

Companies may find collecting and ensuring accuracy, reliability, and consistency of sustainability data across sectors challenging, especially if they haven’t done anything similar before. You need to understand how sustainability impacts financial performance, for example, keep up to date with requirements, and know how these apply to your company. That can be challenging. It’s vital to understand how ‘Organization’ differs from ‘Products’. Impact on emissions from cable production doesn’t equal Prysmian’s total impact on emissions, for example (and required Corporate Social Responsibility data includes much more than emissions).

Prysmian has years of experience with sustainability reporting and working with the Non-Financial Declaration (NFD). This stimulates disclosure in areas where reporting standards are evolving (social, environmental, risk...). New items are added annually, so we have experience with changing requirements and implementing technology and systems to support sustainability reporting. We’ve put a great deal of effort into aggregating data. The latest challenge is addressing evolving requirements ensuring reliability and completeness of information involving a wider audience.