Manufacturing at Prysmian Group: a customer-centric approach to making cables

Different customers have different requests, he said. Some want the factory to be scrubbed spotlessly clean. Some are interested in how the beachfront plant near Naples handles its waste. One client is particularly interested in the environment. Managing these requests is part of D’Ambrosio’s responsibility as head of Arco Felice’s extruded cables production.

“Everyone in the factory knows which customer they are working for,” Dario says.

At Arco Felice, customers and managers work side by side

For Dario D’Ambrosio, a production manager at Prysmian’s Arco Felice plant, a typical day this past summer meant walking around his department to check progress on a €40 million cable link between Capri and Sorrento – and bumping into the customer, Terna.

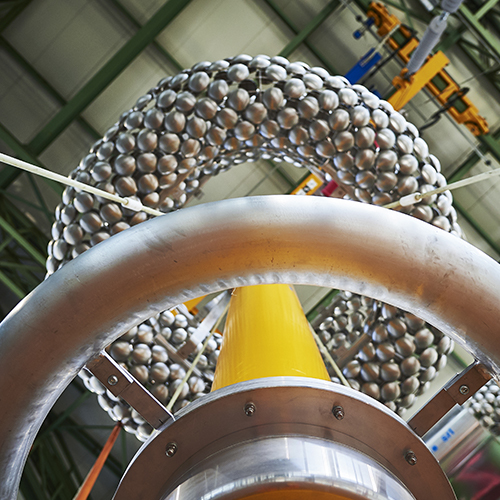

At Arco Felice, one of Prysmian’s four submarine cables plants, every single cable is customized and no two are ever the same. That means when D’Ambrosio’s extruded cables department began making a 32-kilometer HVAC 150 kV cable for Terna, the Italian electricity grid operator’s representatives were in the factory nearly every day checking on the work in progress.

“Customers come to see if we are on track, and what our quality standards are,” says the 32-year-old mechanical engineer from Naples, Italy. “If tomorrow a customer asks us to do something we never did before, we will do it.”

Different customers have different requests, he said. Some want the factory to be scrubbed spotlessly clean. Some are interested in how the beachfront plant near Naples handles its waste. One client is particularly interested in the environment. Managing these requests is part of D’Ambrosio’s responsibility as head of Arco Felice’s extruded cables production.

“Everyone in the factory knows which customer they are working for,” Dario says.

The Arco Felice factory’s manufacturing know how

Prysmian’s leadership in submarine cables would not be possible without the Arco Felice factory’s manufacturing know how. People like Dario are what make it possible for the company to deliver the complex turn-key EPC (engineering, procurement and construction) contracts that will increasingly drive orders in the near future as demand in renewable offshore and interconnector energy markets grows.

D’Ambrosio joined Prysmian in 2016 with the Make It program, seeking international experience and management training. He is responsible for managing 150 to 200 people in shifts of 35 to 40, planning the production of cable by managing tools, lines and raw materials. He must also make sure quality and safety standards are respected.

Arco Felice is one of the first Prysmian factories to hire women in manufacturing roles staring in 2000, and now has about 50 women out of 500 staff. Two and a half years ago D’Ambrosio’s department hired 11 workers, eight of whom were women. After an induction when they were rotated across production lines to gauge their skills and aptitudes, the eight women were employed across all teams.

At Arco Felice, change is an everyday event, whether it means integrating women into the workforce, making quality standards more stringent, improving a production process, or simply moving a pedestrian walkway from one place to another for safety reasons. Sometimes this is hard for people to accept, he says, but it is what makes the factory a centre of excellence.

“What drives us is to make quality cables, using efficiency in terms of human resources and materials,” he says.