Leonardo Da Vinci turns on its main engines

Last December, we witnessed the energization of the vessel’s main switchboards, used to control main power generators. This new year started with the achievement of a new milestone for the Leonardo Da Vinci Vessel: the commissioning of main engines, set for the very beginning of 2021. The engines, installed in Tulcea, Romania, have been effectively turned on for the first time in February 2021.

In Vard’s shipyard in Brattvåg, Norway, the vessel is still undergoing the last outfitting phases, including the finalization of the installation of both rotating platforms, laying sheaves, tensioners, caterpillar and pickup arms. The 100 tons Capstan installation has been finalized. Also, 350 km of Prysmian power cables are installed and used for the Leonardo Da Vinci’s electrical system. All the operations are performed by approximately 500 experts, who are currently working on-site in the shipyard to ensure a flawless vessel’s construction, despite the challenging pandemic situation.

The most efficient and greener engines for a record-breaking vessel

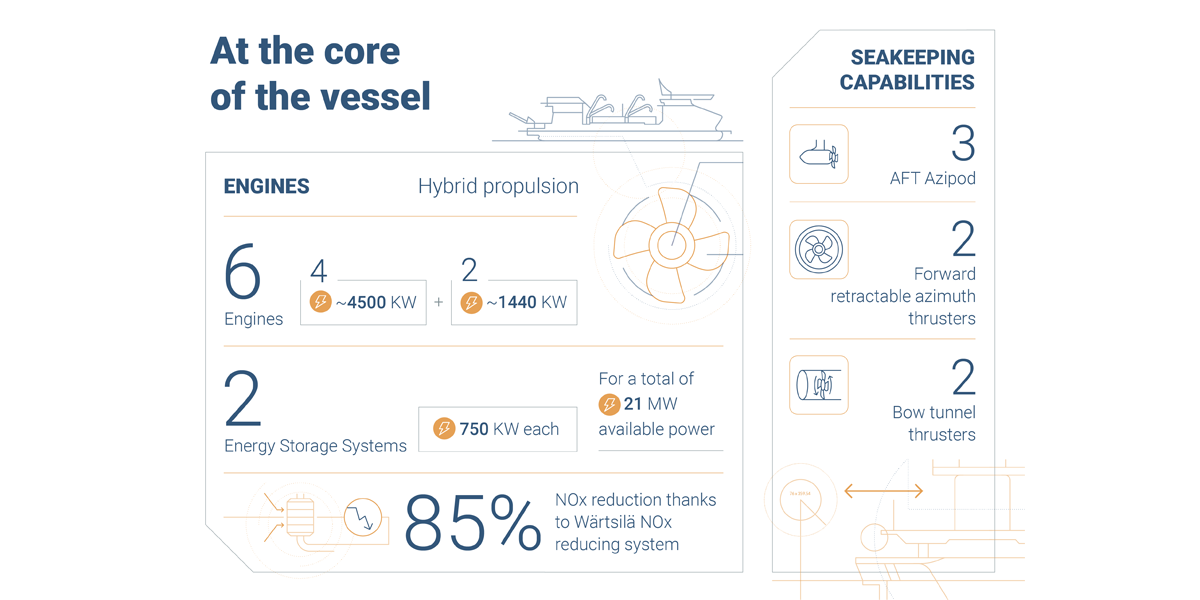

The engine rooms have been set up and the vessel is almost ready for sea trials: with its sustainable features, Leonardo Da Vinci will be a key enabler of the energy transition to a carbon-neutral world by 2050. Leonardo Da Vinci breaks all records for a cable-laying vessel in terms of efficiency, technology, and innovation. The vessel has 2 carousels of 7,000 and 10,000 tons respectively, ensuring the highest carousel capacity in the market, thus improving overall projects’ efficiency. The cable-layer is cutting-edge also in terms of sustainable performance, indeed if we have a closer look to its engines, we can witness that the vessel is powered by the most efficient and greener possible engines. The Leonardo Da Vinci is powered by 6 Wärtsilä hybrid propulsion engines: the main four are able to produce ≈4,500 KW each, while the other two ≈1,440 KW each.

In addition, the vessel features 2 Energy Storage Systems (750 kW each), which are a portion of the total 21 MW available power. Furthermore, the installation of the Class approved Wärtsilä NOx Reducer System shrinks by 85% the emissions of nitrogen oxide based on the Selective Catalytic Reduction (SCR) abatement technique, enabling the vessel to comply with the latest IMO Tier III. Leonardo da Vinci is also designed with an embedded power regeneration system on cable laying equipment that recovers energy, and then send it back to the vessel's power grid.

Leonardo da Vinci has been specifically designed for the only use of Marine Diesel Fuel Oil with a sulphur content minor than 0.1%. It can sail without geographical restrictions, complying with the most recent IMO 2020 (limit < 0.5% sulphur content) and ECA (limit < 0.1% sulphur content).

Furthermore, the vessel is equipped with more than 80% in power of the lighting fittings with low consumption LED lights, thus resulting in a cut in the emissions produced by the generators.

7t Carousel

10t Carousel Installation

Carousel Installation and Crane during Commissioning of Main Engines

Engine Room

Laying sheave assembled

Unique seakeeping capabilities

Leonardo Da Vinci can rely on state-of-the-art DP3 positioning and seakeeping systems: the propulsion system includes 3 AFT Azipods, 2 forward retractable azimuth thrusters and 2 bow tunnel thrusters.

These last-generation features make this vessel a unique asset to maximize Prysmian’s project execution capability, reaching always deeper installations, and consolidate the Group position as a one-stop-shop solution provider.