Global operations,

our key to success

Focus On

Global operations, our key to success

Prysmian Group announced unprecedented investment plans aimed at increasing production capacity and capabilities worldwide. The plans will allow the Group to meet cable demand in the high added value markets with quality and innovative products, while improving efficiency and cost-effectiveness at its manufacturing facilities.

Raising capacity and speeding up manufacturing capability; optimising procedures and processes; focusing on quality and innovation; and supporting people’s development with continuous training. These are the goals set out in Prysmian’s latest initiative, aimed at strengthening its operations worldwide.

This initiative – the global operations enhancement programme – has been introduced to meet today’s growing cable demand in the telecom and power industries. It got off to a successful start in the first half of 2017, as Prysmian managed to complete and set to work its new optical cable plant in Slatina (Romania) and the new MV-HV plant in Yixing (China), while announcing the upgrading of its new fiber optic cables facility in Durango (Mexico).

The entire programme is being developed as part of the Group’s ‘Fast Forward’ approach: Prysmian’s means of improving and harmonising its manufacturing structure, avoiding the waste of resources and leveraging employee know-how and expertise. Andrea Pirondini, COO Prysmian Group, explains that Prysmian implemented the approach in the knowledge that “operational excellence is key to confirming competitiveness, particularly in dynamic and complex markets, such as energy and telecoms”.

R&D activities are driven by the commitment and ideas of our young engineers, who joined the company through the post-graduate programme, launched nearly seven years ago.”

SLATINA BECOMES A FIBRE OPTIC HUB

Slatina

1,000 employees by 2020

Over 10,000 hours of training

Prysmian recently inaugurated its new optical cable plant in Slatina, Romania, the largest of its kind in Europe. The new facility, just like the recently announced optic cables facility in Durango, Mexico, is part of a 3-year, €250 million investment plan aimed at improving the Group’s capacity worldwide, to meet growing demand for optical cables for the deployment of new high-speed telecom networks.

As well as Romania and Mexico, the investment plans includes the Group’s existing optical fibre and cable facilities in Italy, France, the Netherlands, and North and South America, along with a new plant in Prešov, Slovakia. In Slatina, the company is expected to reach 1,000 employees by 2020 and plans to improve production further. The site has become a centre of excellence for optic cables, with a significant commitment to innovation.

“We have a team of 20 engineers who are involved daily in cable design and materials management, as well as product development activities, particularly in high fibre-count cables. Here, we develop high-performing cables with a fibre count exceeding 400, to ensure higher data rates and transmission capabilities,” explains Francesco Fanciulli, CEO of Prysmian’s Central East Europe region.

“R&D activities are driven by the commitment and ideas of our young engineers, who joined the company through the post-graduate programme, launched nearly seven years ago,” continues Fanciulli. “Around 30 highly talented Romanian engineers work at our operations site, mainly within the R&D, manufacturing, product management and supply chain areas. During their training period, they received over 10,000 hours of training to complete their induction and subsequently develop their skills.”

€250 million. The investment plan to improve the Group’s capacity worldwide.

ENHANCING CAPACITY IN MEXICO

Prysmian to boost capacity at its fibre optic plant in Durango, making it the Group’s second-largest manufacturing facility worldwide.

Prysmian is moving fast in Mexico, strengthening its presence in the country to support the rapid growth of the region more fully. The Group recently announced a $15 million investment to enhance the company’s manufacturing capacity in the area, with a new fibre optic cables facility in Durango, which will make the Mexican plant Prysmian’s second-largest manufacturing facility worldwide.

With a manufacturing capability of one million km of fiber per year, expected to grow to two million km in a second stage, the new upgraded facility will be a crucial asset in addressing the growing need for broadband and telecommunications solutions in Mexico and Central America, which is currently growing at 20% every year.

The new plant will provide additional advantages to customers, explained by Juan Alberto Olivares, Prysmian Group’s Technical Market Director for Mexico, Central America, and the Caribbean: “We have all the raw materials needed for this facility here in Mexico. It means that we can produce cables locally, supplying optic cable faster than ever before; and we will be able to quickly react to the needs of the market and those of prospective and existing customers.”

He adds that “within two years, the plant will reach full capacity and we expect to nearly double our regional share in Mexico and Central America to 11% of the market”.

Within two years, the plant will reach full capacity and we expect to nearly double our regional share in Mexico and Central America to 11% of the market.”

PRYSMIAN MEXICO, A GREAT PLACE TO WORK

The Group recently earned the ‘Great Place to Work’ certification for its affiliate in Mexico. The institute that annually awards the best working places stressed how Prysmian has worked on the technical employee and managerial training, and underlined the transparency and quality of organisational communications, support for the personal and professional lives of workers, and the healthy relationships among colleagues.

STRENGTHENING THE CHINA’S GRIP

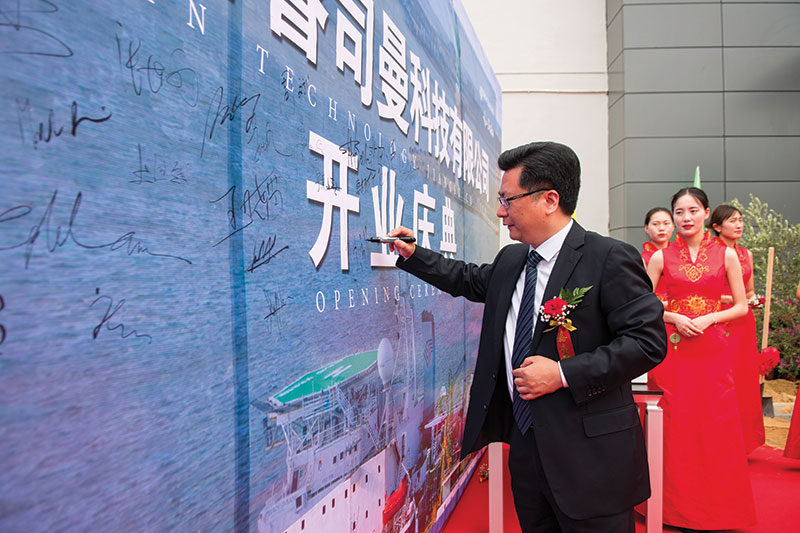

The inauguration of the new MV-HV plant in Yixing marks the opening of a new chapter for Prysmian Group in the Asia-Pacific HV market.

With the inauguration of the upgraded HV-MV plant in Yixing, Prysmian has made its presence in the Asia-Pacific region ever-more strategic, especially – but not exclusively – for the HV systems market. The Group already employs around 1,500 people in China, working in seven manufacturing plants, with the most important located in Suzhou, near Shanghai. At that site, the company has an R&D centre, including a centralised material and testing laboratory. It also boasts manufacturing plants in Tianjin, Yixing, Wuxi and Nantong, and sales offices in Beijing, Shanghai and Hong Kong.

With a cumulative turnover in 2016 of around €430 million, of which €130 million was in the HV business, Prysmian is enjoying a stronger position in a fast-growing market. It further strengthened its grip and increased its independence with the acquisition of the new facilities in Yixing, after it divested its 67% share in a joint venture last year.

Fabio Romeo, Prysmian’s Chief Strategy Officer, states: “This area of the globe is growing fast: faster than other parts of the world, and we think our know-how and technology can make the difference. The Chinese market is really challenging and the competition is strong, but we are working hard to succeed.” Luigi Migliorini, CEO of Prysmian Group China, adds, “Prysmian Group can now offer a wide range of cable technologies and products, including extra high voltage and high voltage cable systems, as well as medium voltage and fire resistant cables, from 6kV to 500kV. The new plant will be capable of producing all the main designs available in the HV systems sector.”

The strengthening of Prysmian in China comes at a time when the Chinese Government is pushing for the “One Belt, One Road” policy, a project in which Prysmian Group, thanks to new investment in Prysmian Technology Jiangsu, is aiming to be a major player.

The plant was acquired for around €42 million and is located in Yixing, a city with more than 1.2 million inhabitants near Shanghai. It boasts manufacturing and logistics facilities over an area of more than 190,000 sqm, with 5 production lines and a capacity of over 20,000 tons per year.