Helping Washington, D.C.

upgrade its power transmission grid

Doing Business

Helping Washington, D.C. upgrade its power transmission grid

Prysmian Group will supply 340 km of High Voltage cables and systems along with the innovative PRY-CAM grid monitoring technology and maintenance services.

Washington, D.C. hit 700,000 residents in 2018, experiencing a dramatic population growth that has caused an increasing demand for reliable electricity supply. Prysmian Group will carry out a multi-phased project aimed at upgrading the US Capital area’s power transmission system. The project is expected to be worth approximately $190 million and is currently scheduled to run between 2019 and 2026.

As a turnkey solution provider, Prysmian Group will be responsible for the design, engineering, procurement, installation and commissioning of High Voltage underground cable systems comprising over 100 km of XLPE-insulated 230 kV cables and over 200 km of XLPE-insulated 69 kV cables, as well as related accessories and network components. The project includes an integrated monitoring system based on the Group’s proprietary and revolutionary PRY-CAM Condition Assessment and Asset Management technology to monitor all key parameters of the electrical system, ensuring effective and preventive management. Prysmian will also be responsible for maintenance services and systems, including sheath testing operations, manhole inspections and voltage testing activities. Cables will be manufactured at Prysmian’s state-of-the-art factory in Abbeville, South Carolina.

SUBMARINE POWER LINKS IN THE BOSTON AREA…

Prysmian Group won an important contract in the US to develop a power interconnection between Deer Island and the mainland power grid in the capital of Massachusetts.

Following the acquisition of General Cable, Prysmian Group has won an important contract in the Boston area that gave the group the opportunity to consolidate its presence in the US interconnection market. The Caldwell Marine International LLC, a US construction contractor specialising in submarine utility operations, awarded the Group a new contract for the design, manufacture, supply and testing of a 6 km 3x630 mm² 115 kV submarine cable system with XLPE insulation, plus all related cable accessories, to connect Deer Island to mainland Massachusetts in the US.

Prysmian will also be responsible for the project’s land section, for which it will supply and install 8 km of 115 kV land cabling, along with all related accessories. All of the submarine cables will be produced at Prysmian’s centre of excellence, located in Arco Felice in Italy, while the land cables will be manufactured at Prysmian’s state-of-the-art factory in Abbeville in South Carolina, USA, thus offering local expertise to the US market through high-quality products and cable solutions.

Hakan Ozmen, Executive Vice President – Projects of Prysmian Group, commented: “By winning this key contract Prysmian has again confirmed its historical leadership in the US market, both in high voltage underground and submarine cable business solutions. The impressive track record in delivering complete cable solutions in the US market will identify Prysmian as well-equipped to capture any market opportunities that arise”.

…AND OFF CANADA’S EASTERN SHORES

New contract awarded to connect islands in the Passamaquoddy Region of the Bay of Fundy.

Some hundreds of kilometres north of the Boston project, Prysmian Group won another contract worth €17 million by New Brunswick Power Corporation (NB Power), the largest electric utility in the Canadian Atlantic based in the province of New Brunswick. The Fundy Isles Project involves the development of a new submarine cable link, which will allow the upgrade of the capacity of the existing submarine transmission system in the Passamaquoddy Region of the Bay of Fundy.

The new power cable link will connect Deer Island, Campobello Island and Grand Manan Island to the mainland power grid in the Canadian province.

Prysmian Group will design, manufacture and install a 300 mm² 69 kV three-core submarine cable system with XLPE insulation for a total of 20 km. Core cables will be produced at Prysmian’s centre of excellence in Montereau, France, while the cable armouring will be manufactured at Prysmian’s state-of-the-art factory in Nordenham in Germany, part of the Group after the merger with General Cable.

“This project is particularly challenging for Prysmian as the section where the installation activities will be performed presents the highest tides in the world, with very strong currents,” stated Raul Gil, Prysmian Group Submarine Business Director.

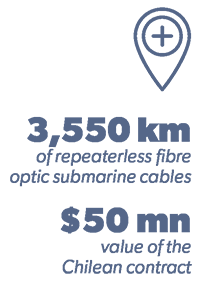

STRATEGIC SUBMARINE TELECOM PROJECT SECURED IN CHILE

The first submarine telecom interconnection obtained after the acquisition of General Cable, a milestone contract that marks Prysmian Group’s return to the strategic submarine Telecom cable business.

Prysmian Group will develop a strategic cable system that will greatly improve Chile’s telecom and broadband infrastructure, while also connecting the country’s many underserved regions to a state-of-the-art, high-speed broadband fibre network. The new milestone contract, that marks the return of the Group to the important business of submarine telecom cables, has been awarded by Gtd Teleductos S.A., a Chilean telecom operator. Under the contract, worth some $50 million, Prysmian will develop a turnkey repeaterless submarine cable system connecting Arica to Puerto Montt in Chile. The contracts have been secured through the Group’s submarine telecom division NSW, which became part of Prysmian Group following the acquisition of General Cable.

Hakan Ozmen, EVP Projects, stated that “this contract represents a significant milestone for Prysmian Group as it is the first submarine telecom interconnection project obtained after the acquisition of General Cable. It marks Prysmian’s return to this business and is further proof of the excellent quality of our cables. It not only confirms that Prysmian Group is a preferred partner of choice for submarine projects, but also that it is committed to supporting the development of innovative network infrastructures worldwide”.

The project involves the design, supply and installation of more than 3,550 km of repeaterless fibre optic submarine cables. Prysmian will supply 11 cable segments of a length ranging from 135 km to more than 400 km. The cables will be produced at Prysmian’s state-of–the-art production facility in Nordenham, Germany, which became part of the Group as a result of the acquisition of General Cable. From this project, we envisage a repeaterless festoon system that will provide telecommunication connectivity to the whole country, as well as linking Chile to Central and North America.

COOPERATION AGREEMENT IN SAUDI ARABIA

Prysmian Group has signed a Memorandum of Understanding with GCC Electrical Equipment Testing Laboratory located in Dammam, Saudi Arabia, for joint technical cooperation aimed at developing services associated to testing, inspection and certification activities in the GCC region. The agreement represents the acknowledgment of Pry-Cam Technology for Partial Discharge measurements as the ultimate resource for the effective management of electrical systems. In fact, Prysmian will cooperate with GCC Lab to perform Partial Discharge (PD) tests - based on the Group’s proprietary PRY–CAM wireless technology - on behalf of third parties, both inside and outside the GCC Lab.

LINKING SOLAR ENERGY TO THE WORLD’S POWER NEEDS

Prysmian Group launches PRYSUN, its global solar PhotoVoltaic wire compliant with the most recognized global standards.

The main keys to a successful PV installation are the design of the PV system, the quality of the PV components and a correct installation. When talking about PV components, the primary focus is on modules, inverters and panel support structures. These components are crucial in the installations and represent a major part of the investment. The PV wire is undeniably a critical system component.

The PV are part of the Balance of System in a PV installation and represent only 1-2% of the total installation cost. PV cables are a crucial part of any PV installation. PV wires, that meet the industry standards, are good quality and are sized properly, provide safety and longer-lasting systems. PV wire failures disrupt power generation which leads to replacement of the cables and replacement costs. The initial investment in good quality PV cables becomes immaterial compared to the potential risk stemming from the use of low performance cables. Prysmian Group’s solar PV cable portfolio is composed of three brands: TECSUN – the premium brand made in Germany with over 15 years of experience and more than 1,000,000 km sold. This cable outperforms the standards of PV cables, is suited for the roughest conditions and for direct burial; PRYSUN – the newest global brand resulting from the combination of Prysmian Group and General Cable. It is compliant with European standard EN 50618 and the International standard IEC 62930; SUNGEN – the regional brand for markets like North American with local standards such as UL/CSA.

The Group’s solar PV cables are designed for the interconnection of various elements in photovoltaic systems, including panel interconnection, between panels and combiner boxes or from combiner boxes to the inverter. For many years, there has not been an international standard for photovoltaic cables. At the end of 2017, the new IEC 62930, the first international standard for PV cables, was issued. PRYSUN is the result of synergies between Prysmian Group and General Cables R&D teams, with a global technology and know-how sharing to find the best solutions. Due to Prysmian Group’s global presence, PRYSUN is available regionally with manufacturing in multiple locations. Prysmian Group offers also complete cables solutions to enable the production and supply of solar photovoltaic energy. In addition to the solar PV cables, Prysmian Group’s cable portfolio includes low, medium and high voltage cables according to the most known standards of each region, as well as special cables for communication and control.

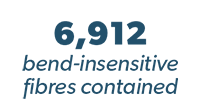

FLEXRIBBON MET THE HIGHEST FIBRE COUNT EVER

Prysmian Group continues to support the development of worldwide broadband networks with outstanding optical fibre and cable innovation. The Group recently presented its industry record 6,912 fibre FlexRibbon™ cable at the Optical Networking and Communication Conference & Exhibition in San Diego. The world leader in the cable industry, took the occasion of the Californian event to present to the market its 6,912 fibre MassLink™ Cable with FlexRibbon™ Technology, meeting the highest fibre count within the industry. With this amount of fibre in a single cable, Prysmian concentrated on a product design that would provide installers and splicers with craft friendliness and superior fibre management. The 6,912 fibre FlexRibbon provides an ultra-compact outside plant cable design that contains 6,912 bend-insensitive fibres, with a cable diameter small enough to fit into a 50.8mm/2” duct. By using FlexRibbon technology, ribbons are rolled up and packed together in small diameter sub-units.