German HVDC

cable projects

Enabling Europe’s clean energy transition

Prysmian Group, the world leader in the energy and telecom cable systems industry,is playing a key role in developing three vital energy projects that will transport the clean energy generated by wind power off the northern shores of Germany to the industry packed South of the country, home of the European powerful productive engine, in a process that will help the entire Union’s energy transition.

The three innovative state-of-the art HVDC cable connections will contribute to achieving decarbonization goals. To do so, Prysmian will develop smart and sustainable power grid infrastructures to support the energy transition in Germany and Europe.

The three innovative state-of-the art HVDC cable connections will contribute to achieving decarbonization goals. To do so, Prysmian will develop smart and sustainable power grid infrastructures to support the energy transition in Germany and Europe.

Prysmian Group introduces German HVDC power transmission projects

Three innovative underground cable systems

Three cable projects at the core of Europe’s transition

Germany has opted for an ambitious solution on its road to decarbonization. It will install three major underground cables by 2027 running a total route length of 1,500 kilometres, to transport electricity from wind farms in the North Sea across the country to power cities and factories in the south. These projects place Germany in the forefront of Europe’s climate change efforts.

Prysmian Group will supply about 2,300 kilometres of the projects’ cables, supporting Germany’s and Europe’s energy transition in a sustainable, enduring, future-proof way.

Transporting energy from Germany’s north to south

A-Nord

Read More

Type of cable: ±525 kV P-Laser

Forecasted completion: 2027

Prysmian cable route: 300 km

Forecasted completion: 2027

Prysmian cable route: 300 km

A-Nord was awarded to Prysmian Group by German grid operator Amprion GmbH to design, manufacture, supply, lay, joint, test and commission a 1 GW ±525 kV HVDC underground cable system insulated with proprietary P-Laser technology, on more than 300 km, from Emden in Lower Saxony to Osterath in North Rhine-Westphalia.

SuedLink

Read More

Type of cable: ±525 kV XLPE

Forecasted completion: 2026

Prysmian cable route: 580 km

Forecasted completion: 2026

Prysmian cable route: 580 km

SuedLink was awarded to Prysmian Group by German transmission grid operators TransnetBW GmbH and TenneT TSO GmbH with the assignment to design, manufacture, supply, lay, joint, test and commission a 2 GW ±525 kV HVDC underground cable system on a route of 580 km, from Wilster in Schleswig-Holstein to the southern connection point at Bergrheinfeld, Bavaria.

SuedOstLink

Read More

Type of cable: ±525 kV P-Laser

Forecasted completion: 2025

Prysmian cable route: 270 km

Forecasted completion: 2025

Prysmian cable route: 270 km

SuedOstLink was awarded to Prysmian Group by German grid operator TenneT TSO GmbH with the assignment to deliver a ±525 kV HVDC underground cable system, with transmittable power of 2 GW on a single system ,over a route of 270 km starting at the Southern Germany connection point at Isar, close to Landshut in Bavaria.

Significantly involved in three German HVDC cable projects

Prysmian Group has been awarded contracts worth more than €1.8 bn for the three underground cable projects: SuedLink, SuedOstLink and A-Nord. The required underground lines - the longest in the world - will use a new, higher voltage cable technology that allows for narrower trench widths. Prysmian will work with its dedicated local project engineering and management teams to carry out design and installation works, and in addition will provide all accessories and the integrated PRY-CAM monitoring system.

Go To Page - Energy transition projects

Go To Page - Energy transition projects

Delivering Europe’s energy transition

The energy transition from fossil fuels to renewable power sources is already underway and the independence from energy imports has become even more important. It is taking place mainly in the power sector, where renewable energy now accounts for 26% of electricity generation worldwide. Given the existential threat posed by continued use of fossil fuels, the European Union has taken the global lead in fighting climate change and in reducing energy dependency by setting ambitious targets already significantly before 2030. The European Commission’s European Green Deal is asking member states to become carbon neutral by 2050. This can only be achieved by an integrated energy market that is both, digitalized and interconnected, powered by renewable sources.

By the end of 2022, Germany will shut down the last three of its 17 nuclear power plants, and, as of now, will close all of its coal-fired electricity plants by 2030 as part of its shift to a fossil fuel-free economy by 2050. Europe’s industrial powerhouse intends to rely on renewables such as wind, solar, biomass, and hydropower to make up 65% of the energy mix by 2030. Therefore, Germany is making a massive investment in renewable energy, including investment in its electricity grid to bring it up to the task of transporting wind energy generated in the north to where it is needed in the southern regions. Given the country’s status as Europe’s biggest economy, Germany’s transition is decisive for the EU’s overall ability to implement a more sustainable, secure, and independent economy.

Cables are the backbone of Europe’s energy transition and energy security. A flexible electricity grid and interconnectors capable of shifting power across borders are needed to transport wind, solar, and hydro power safely, rapidly and at a lower cost. Prysmian Group supports Europe’s national Transmission System Operators (TSOs) and plans to build up this smarter and more robust grid with intelligent solutions both in terms of products and systems.

A key partner for German energy companies

Prysmian is the leading cable supplier to German energy utilities, with approximately 1,900 local employees and 6 manufacturing plants: Nordenham, Schwerin, Berlin, Neustadt near Coburg, Nuremburg and Wuppertal.

Prysmian’s 4 R&D centres in Germany mean it can work closely together with local customers. The German HDVC cables projects were awarded by European grid operators TenneT, TransnetBW and Amprion to Prysmian in 2020, which makes Prysmian the only cable manufacturer involved in all three German HVDC cable projects.

Six offshore wind farms now operating in Germany’s North Sea are being powered by HVDC submarine cables installed by Prysmian: BorWin2, BorWin3, DolWin3, HelWin1, HelWin2, and SylWin1. A seventh, DolWin5, is currently under construction.

These are some of the windfarms generating the electricity that will be transported by the three German HVDC cable projects in order to supply sustainable energy to cities and factories in Germany’s industrial south.

World class technical solutions

No connection is too long or too deep for Prysmian Group. In order to support and enable the most efficient energy transition possible, Prysmian Group has developed world class technical solutions that range from bigger cables and conductors allowing for more power transmission and lower energy losses, to longer connections and deeper subsea links.

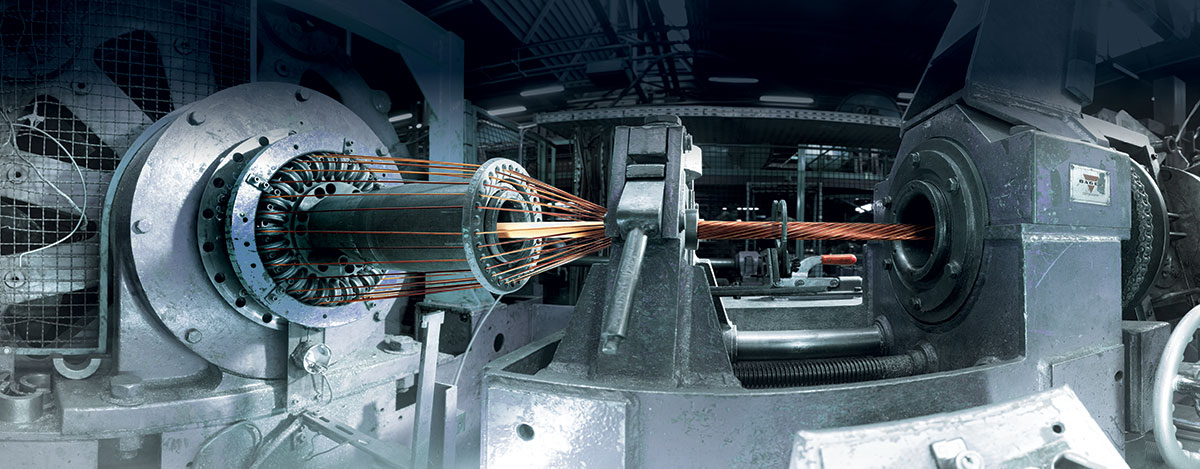

The development of HVDC cables for voltages up to 600 kV grows out of Prysmian’s 140-years’ experience. The German HVDC cable projects use Prysmian Group’s powerful ±525 kV HVDC underground cable technology that makes it possible to transmit more power over long distances, especially from sources like offshore wind farms.

Another advantage of ±525 kV is that it allows for a reduced quantity of underground cable to transmit the same power (if compared to ±320 kV), requiring less space, narrower trenches and less disruption to residents when installing the system.

For a large project like this, the advantage of ±525 kV is significant.

These cables are insulated with two solutions: P-Laser and XLPE.

P-Laser cable technology is based on High Performance Thermoplastic Elastomer insulation that is fully recyclable - which will become relevant during the decommissioning stage of old HVDC links after 40 years. Another advantage is that it is quicker to manufacture than XLPE coatings because it does not require the time-consuming degassing process.

XLPE is a cross-linked polyethylene-based insulation, with a dedicated formula for DC systems application. XLPE technology’s main advantages are longer transmission lengths with lower system losses. Prysmian Group is using it for the SuedLink running the length of Germany, from Wilster in Schleswig-Holstein (located to the northwest of Hamburg), down to the southern connection point at Bergrheinfeld, close to Schweinfurt in Bavaria.

Moreover, P-Laser technology is fully compatible with existing cable accessories and can be integrated in networks using different insulation technologies. Prysmian Group is using P-Laser insulation for the SuedOstLink and A-Nord.

Impact on local communities

Prysmian Group is a company accustomed to setting records and achieving new milestones. With about 2,300 kilometres of cable to manufacture and install, it’s clear that Prysmian Group will reach a new level of execution excellence with the German HVDC cable projects. To carry out this massive job, Prysmian has opened 3 new regional offices in Bayreuth, Würzburg and Wuppertal and set up a multicultural project development and management team of over 200 employees.

The team is led by Alberto Boffelli, COO Project BU and Heiko Dirks, Continental Europe Regional Director for Project Management.

SuedOstLink was the first of the three projects to get started in November 2020, with a multi-cultural team recruited from the area near Bayreuth. Commissioned by grid operator TenneT, the SuedOstLink cable runs from Saxony-Anhalt in the heart of Germany south to the Isar power station near Munich and has been recognized by the European Union as a “project of common interest.”

Go To Page - Prysmian sets up the organisation for the development of the 3 German power transmission cable projects

Go To Page - Prysmian sets up the organisation for the development of the 3 German power transmission cable projects

Environment and stakeholder

All units certified

according to ISO 9001 and ISO 14001 Full compliance with the highest international environmental and quality standards

according to ISO 9001 and ISO 14001 Full compliance with the highest international environmental and quality standards

~200-people

multicultural team recruited for the three projects

multicultural team recruited for the three projects

3 new offices

in Germany to boost our customer proximity

• Bayreuth

• Wuerzburg

• Wuppertal

in Germany to boost our customer proximity

• Bayreuth

• Wuerzburg

• Wuppertal

“Zero defects” and “Right first-time” approach

First cables delivered for SuedOstLink

Every big journey starts with a small first step. In December 2021, Prysmian reached an early milestone when it completed manufacturing and testing of the first lot of cables in projects calling for about 2,300 kilometers of them – the distance from London to Brindisi in the heel of Italy’s boot.

This first portion of cables – a total of 9 drums, each with 1,750 metres of underground cable and weighing 83 tons each – was transported by ship from Prysmian’s plant in Gron, France, to an intermediate storage area in Regensburg, Germany, where the cables will await installation in an underground trench. Overall, Prysmian will produce a total of around 550 kilometres of underground cable for an approximately 270 kilometres long section of the SuedOstLink (starting at the Southern Germany connection point at Isar, close to Landshut in Bavaria).

Prysmian's ±525 kV HVDC underground cable is designed with large conductor cross-sections for high transmittable power over long distances. This means the trench width is smaller than for 320 kV systems, requiring less construction effort when installing the system. These cable systems will include an integrated PRY-CAM monitoring system for wireless recording and monitoring of the system status.

Go To Page - Prysmian sets a milestone in the realization of new German HVDC power transmission line

Go To Page - Prysmian sets a milestone in the realization of new German HVDC power transmission line