525 kV HVDC

NEW CABLE SYSTEMS

FOR THE ENERGY TRANSITION

FOR THE ENERGY TRANSITION

525 kV HVDC

NEW CABLE SYSTEMS

FOR THE ENERGY TRANSITION

FOR THE ENERGY TRANSITION

Connecting the world.

Today and in the future.

As a company, we can play a crucial role

in the global energy transition

We operate in the business of high voltage underground and submarine cables and systems for power transmission and distribution, special cables for applications in many different industries and medium and low voltage cables for the construction and infrastructure sectors.

We manufacture cables and accessories for voice, video and data transmission for the telecom industry, offering a comprehensive range of optical fibres, optical and copper cables and connectivity systems.

Sustainability is in our DNA

Prysmian’s ambition is to act as an enabler to accelerate the energy transition, while also creating business value, by supporting the development of greener and smarter power grids with innovative cable technologies to cover longer distances and sea depths, ensuring higher performance, reliability and sustainability. This ambition is demonstrated by our everyday business activities to provide clean energy where it is needed, all over the world. Interconnectors between countries are another key part of the energy transition: as the backbone of power grids, cables are, and will be an essential part of this development, supporting the implementation of larger, more integrated, efficient and sustainable power transmission systems.

525 kV cable technology, a step further

More efficient, reliable, eco-friendly

power transmission

Prysmian Group launched the new 525 kV HVDC cable technology, making a significant step forward towards more efficient, reliable and eco-friendly power transmission.

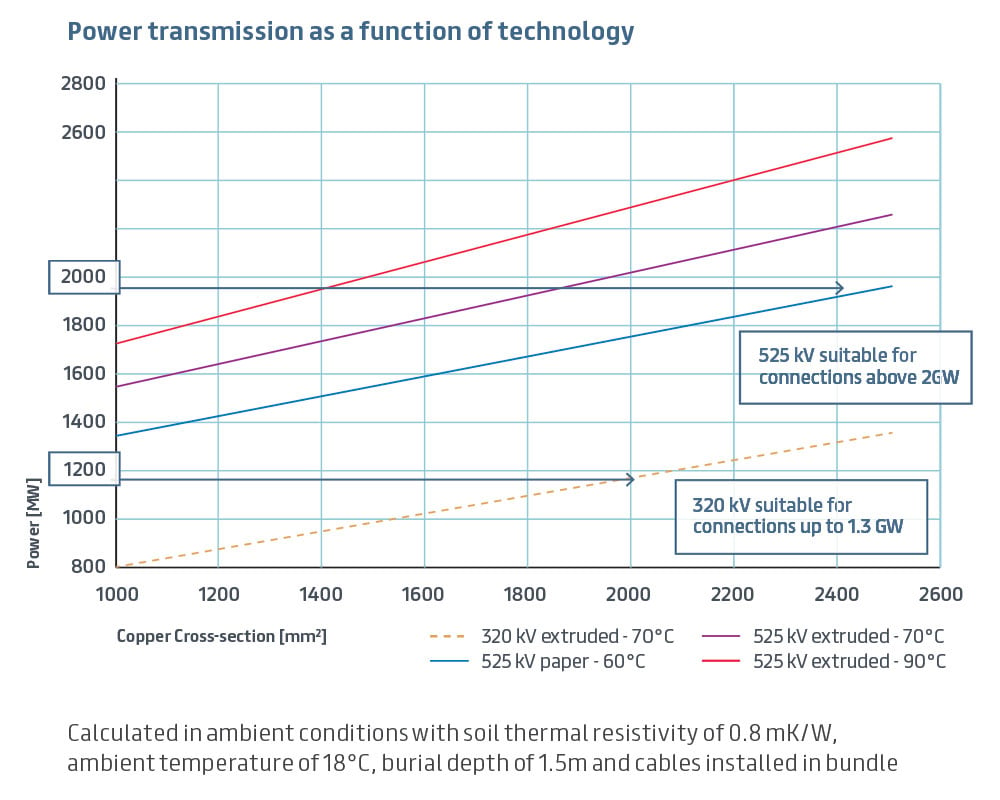

525 kV extruded land cable systems are qualified with two different insulation materials, P-Laser and XLPE. They are both designed to operate at very high electrical stresses and are tested with large conductor cross-sections to maximize power transmission over long distances with minimized land use. For example, the ±525 kV technology uses less cable to transmit the same power compared to classic 380 kV AC systems. This is reflected in less construction efforts when installing the cables and narrower trench widths. P-Laser also benefits from a higher operating temperature than classic HVDC systems at 320 kV, further increasing its power transmission capacity.

525kV systems are effective solutions able to connect power generation areas such as wind generation-rich regions to major consumption centers, typically located far from renewable energy sources, reducing the required land usage and ensuring lower environmental impact.

A continuous effort towards the energy transition

Prysmian Group wanted to take things a stepfurther confirming its role and commitment in the development of power grid infrastructure, empowering its customers in the continuous effort towards the energy transition to reach the EU 2050 goal of having 300 GW of offshore wind power and also reducing infrastructure costs for the benefit of energy bills and final consumers.

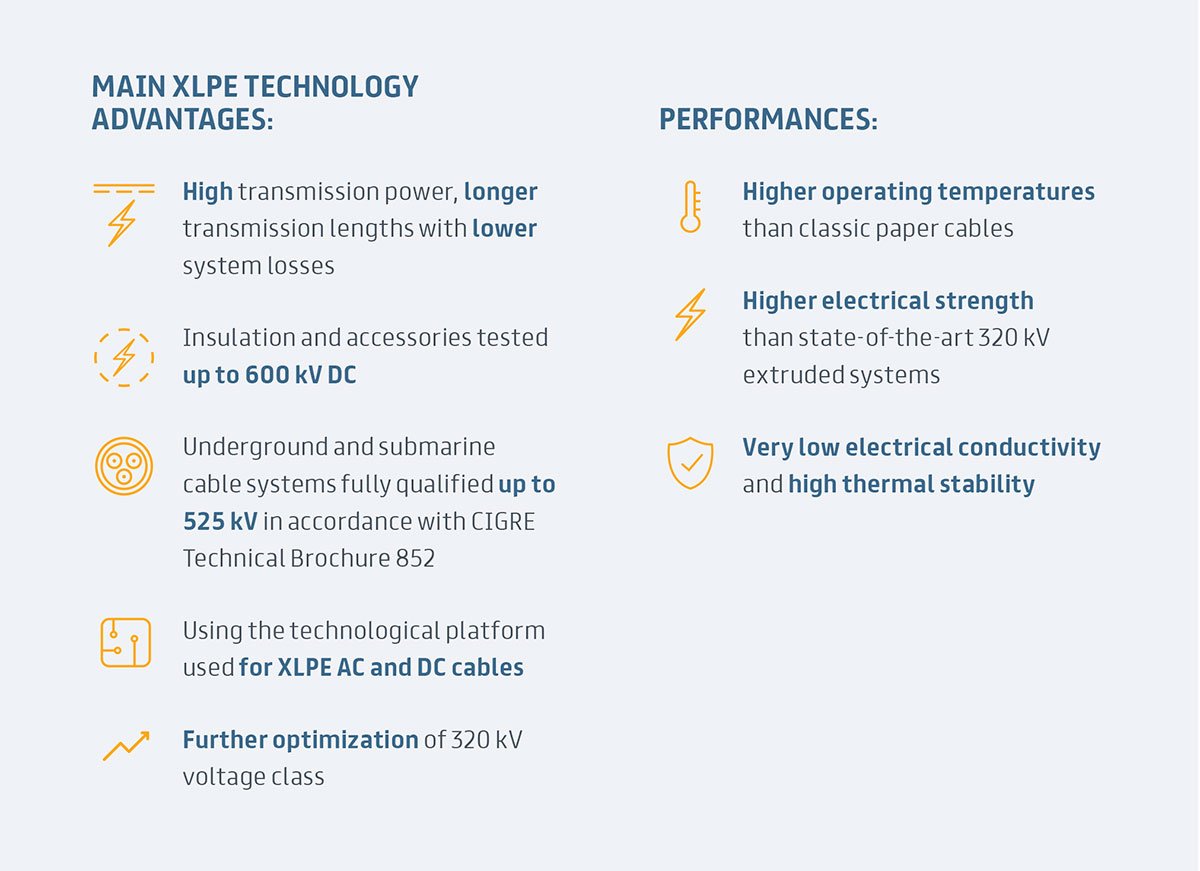

XLPE technology

XLPE insulation technology is based on polyethylene and requires a cross-linking process, which is essential for stabilizing the insulation material. This process determines the presence in the insulation of crosslinking by-products (such as methane, cumyl alcohol,acetophenone, etc.). These by-products should be removed, after the crosslinking with a specific thermal treatment process, known as “degassing”.

The degassing operation decreases the amount of residual by-products present in the cable. Electrical and thermomechanical working performance should be selected accordingly, to guarantee reliable system operations at the ever-increasing voltage levels.

The newly developed XLPE material presents higher cleanliness and lower electrical conductivity, allowing for an increase of the maximum allowable electrical stresses in the insulation (if compared to the previous XLPE materials), meaning that the conductivity is more stable between cold and hot conditions. As a result, it is possible to reach cable voltage levels up to 600 kV, while reducing thicknesses at standard voltages with lighter and less expensive cables.

XLPE Land

Read

Datasheet

Datasheet

Indicative diameter

140 mm

Dimensional data for 3000 mm2 copper

Indicative cable weight

40 kg/m

Ohmic resistance

0.0060 Ω/km

Dimensional data for 3000 mm2 copper

Coaxial inductance

0.14 mH/km

Capacitance

0.24 μF/km

XLPE Submarine

Indicative diameter

160 mm

Dimensional data for 2500 mm2 copper

Indicative cable weight

65 kg/m

Ohmic resistance

0.0072 Ω/km

Dimensional data for 2500 mm2 copper

Coaxial inductance

0.15 mH/km

Capacitance

0.22 μF/km

Read

Datasheet

Datasheet

The energy transition from fossil fuels to renewable power sources is already underway and the independence from energy imports has become even more important. It is taking place mainly in the power sector, where renewable energy now accounts for 26% of electricity generation worldwide. Given the existential threat posed by continued use of fossil fuels, the European Union has taken the global lead in fighting climate change and in reducing energy dependency by setting ambitious targets already significantly before 2030. The European Commission’s European Green Deal is asking member states to become carbon neutral by 2050. This can only be achieved by an integrated energy market that is both, digitalized and interconnected, powered by renewable sources.

By the end of 2022, Germany will shut down the last three of its 17 nuclear power plants, and, as of now, will close all of its coal-fired electricity plants by 2030 as part of its shift to a fossil fuel-free economy by 2050. Europe’s industrial powerhouse intends to rely on renewables such as wind, solar, biomass, and hydropower to make up 65% of the energy mix by 2030. Therefore, Germany is making a massive investment in renewable energy, including investment in its electricity grid to bring it up to the task of transporting wind energy generated in the north to where it is needed in the southern regions. Given the country’s status as Europe’s biggest economy, Germany’s transition is decisive for the EU’s overall ability to implement a more sustainable, secure, and independent economy.

Cables are the backbone of Europe’s energy transition and energy security. A flexible electricity grid and interconnectors capable of shifting power across borders are needed to transport wind, solar, and hydro power safely, rapidly and at a lower cost. Prysmian Group supports Europe’s national Transmission System Operators (TSOs) and plans to build up this smarter and more robust grid with intelligent solutions both in terms of products and systems.

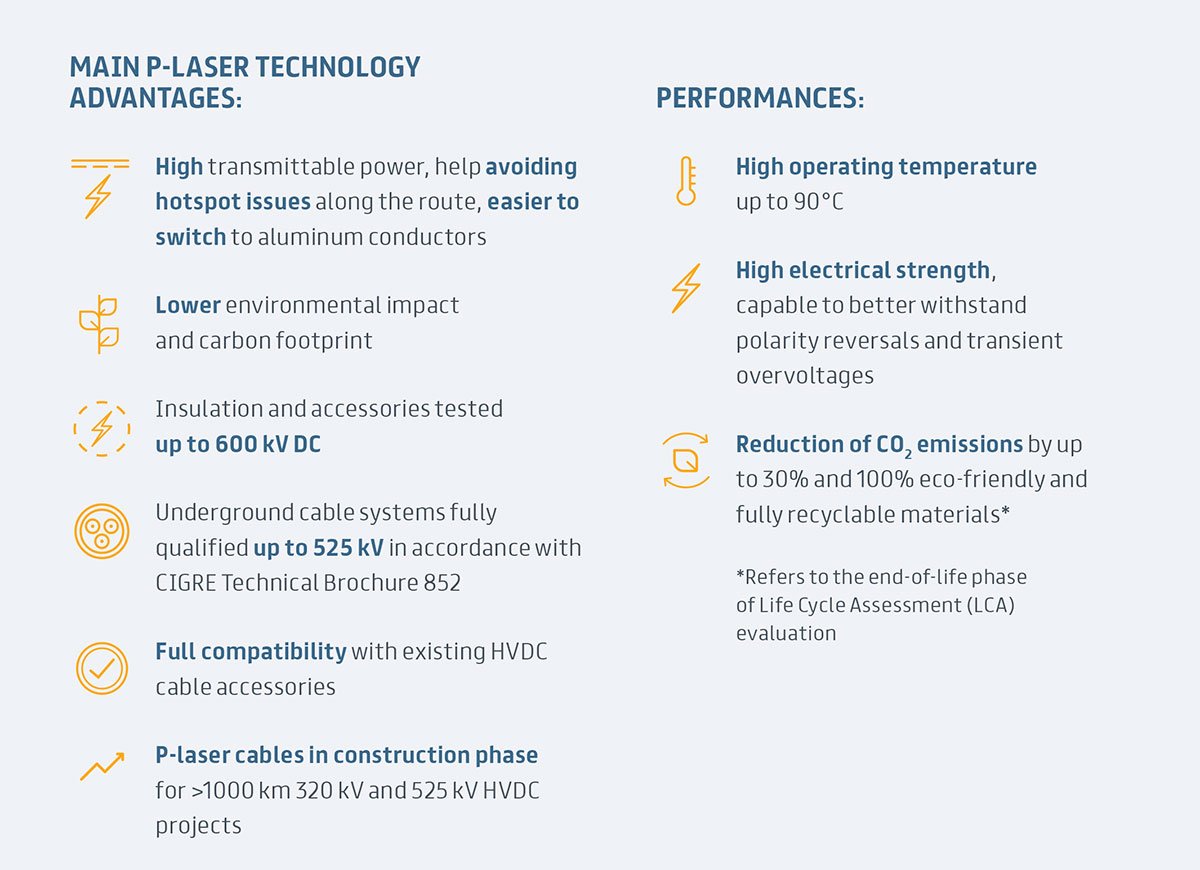

P-Laser technology

P-Laser cable technology is based on a High-Performance Thermoplastic Elastomer (HPTE) insulation, an in-house developed insulation material based on polypropylene. The excellent electrical properties of polypropylene are well known; however, intensive R&D work was needed to achieve a combination of excellent values of flexibility and thermomechanical properties. Compared to XLPE, HPTE does not require any crosslinking process and therefore does not require the time and energy consuming degassing process. Being intrinsically free of any cross-linking by products, P-Laser insulation performances are outstanding, and it can safely withstand demanding electrical stresses such as polarity reversals and transient overvoltages.

HPTE is designed for operation at 90°C. This allows, in comparison to operation at 70°C, to either transmit more power or to reduce the cable cross section and thus investment costs. Also, this feature can be used to operate the link at increased safety margins.

P-Laser is fully recyclable, a key advantage for the end of life stage of obsolete HVDC links. As the production process with P-Laser has a low energy consumption, it has an overall reduced carbon footprint compared to XLPE up to 30%. P-Laser technology is fully compatible with existing cable accessories and can be integrated in networks using different insulation technologies.

P-LASER Land

Read

Datasheet

Datasheet

Indicative diameter

155 mm

Dimensional data for 3500 mm2 aluminum

Indicative cable weight

25 kg/m

Ohmic resistance

0.0081 Ω/km

Dimensional data for 3500 mm2 aluminum

Coaxial inductance

0.13 mH/km

Capacitance

0.25 μF/km

P-LASER Submarine

Indicative diameter

160 mm

Dimensional data for 2500 mm2 aluminum

Indicative cable weight

50 kg/m

Ohmic resistance

0.0119 Ω/km

Dimensional data for 2500 mm2 aluminum

Coaxial inductance

0.15 mH/km

Capacitance

0.22 μF/km

Read

Datasheet

Datasheet

Prysmian is the leading cable supplier to German energy utilities, with approximately 1,900 local employees and 6 manufacturing plants: Nordenham, Schwerin, Berlin, Neustadt near Coburg, Nuremburg and Wuppertal.

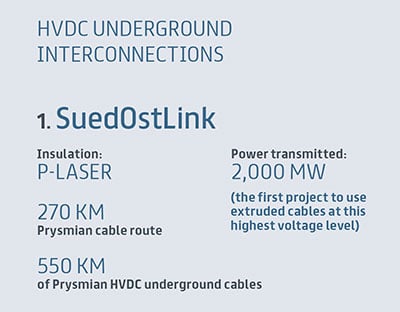

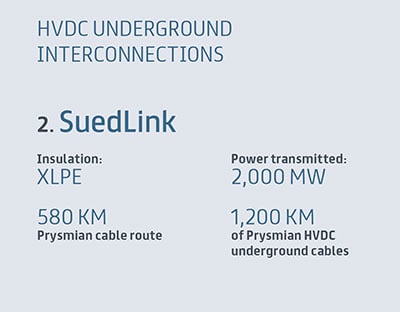

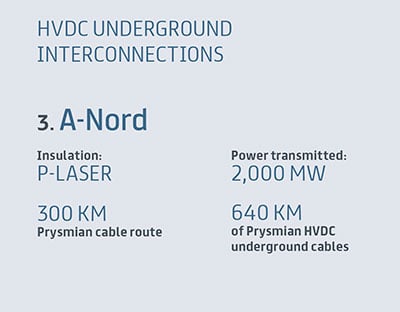

Prysmian’s 4 R&D centres in Germany mean it can work closely together with local customers. The German HDVC cables projects were awarded by European grid operators TenneT, TransnetBW and Amprion to Prysmian in 2020, which makes Prysmian the only cable manufacturer involved in all three German HVDC cable projects.

Six offshore wind farms now operating in Germany’s North Sea are being powered by HVDC submarine cables installed by Prysmian: BorWin2, BorWin3, DolWin3, HelWin1, HelWin2, and SylWin1. A seventh, DolWin5, is currently under construction.

These are some of the windfarms generating the electricity that will be transported by the three German HVDC cable projects in order to supply sustainable energy to cities and factories in Germany’s industrial south.

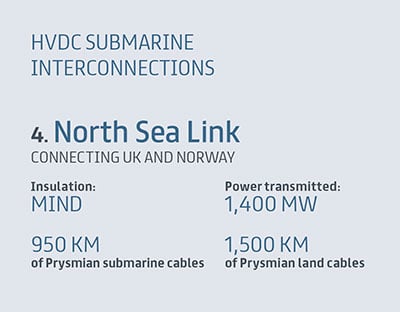

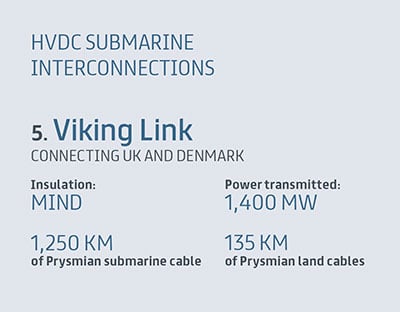

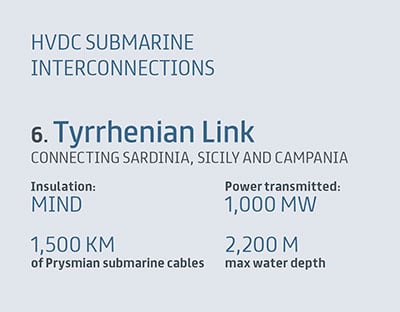

Mass Impregnated non drained technology

Mass Impregnated Non Drained (MIND) cables are suitable for voltages of up to 600 kV DC. The insulation consists of high-density paper tapes impregnated with a high-viscosity compound which does not require fluid pressure feeding, thus allowing cables to be installed in HVDC links in very long lengths, up to several hundreds of kilometers. Nevertheless, they have intrinsic limitations in power given by kraft paper’s electrical and thermal performances.

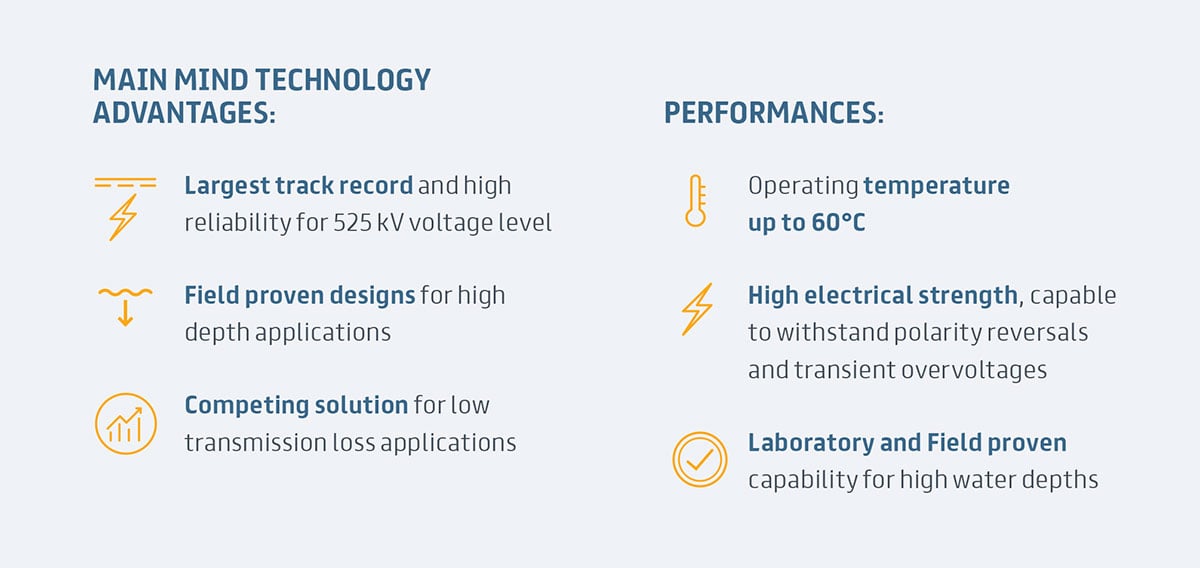

Research and development work on materials and technologies carried out by Prysmian over the years has led to a product that can operate up to 60°C and has the longest track record of operation at 525 kV voltage level. MIND cables are still of interest for all applications where thermal performances are limited by other factors or aren’t the main design driver, such as limitation of transmission losses, environmental constraints, or high depth applications.

Prysmian’s special armour design enables record installation depths exceeding 2200 m, using special armour design features also developed by Prysmian. MIND cables are the only technology installed and in operation at 1600 m. For high depth applications ,mechanical constraints reduce the cross-section disadvantage with extruded cables.

The thin insulation package typically used in MIND cables is beneficial in reducing the cable weight and pulling tensions during installation. This doesn’t affect the current rating, as thermal conditions at high depths are more favorable thanks to lower temperatures and large distances between pole cables, not installed in bundle.