Burj Khalifa: sky-high safety

Burj Khalifa:

It dominates the Dubai skyline and can boast more than one world record: its 828 metres make it the tallest building ever constructed and the lifts connecting its 162 floors reach unparalleled speeds (10m/sec).

“Including electrical circuits, fire alarm systems and emergency lighting systems and lifts, the length of the cables installed by Prysmian is 1,300 times greater than the height of the tower.”

It is the Burj Khalifa, meaning “caliph tower”: the beacon of the most innovative high-tech architecture and humankind’s eternal challenge against Nature and against its own limits.

A micro-world buzzing with life that every day uses an impressive amount of electricity for its lights and lifts.

An authentic engineering work of art designed to reach the stars despite its awe-inspiring size and withstand Dubai’s summer temperatures, the Burj Khalifa receives thousands of visitors every day and is — most significantly — the first building of this height to be lived in.

A huge responsibility

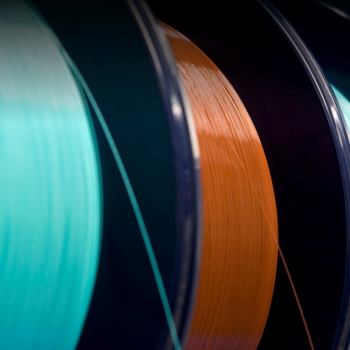

The high population density, combined with the building’s unique features, makes this project a truly ambitious endeavour. Prysmian Group took on the challenge. In addition to supplying the Burj Khalifa’s essential electrical circuits, it managed the delicate issue of fire safety systems and the crucial matter of lift performance.

Guaranteeing safety, even in extreme situations

Priority is safety in case of fire: the materials used and the detection systems have to be excellent. To power the fire alarm and emergency lighting systems, Prysmian Group supplied its low voltage cables, from the FP range, which couple low flame spread and heat release with very low emission of smoke and dangerous gases in the event of a fire. This grants guests longer time to evacuate the building and ensures better operating conditions for the emergency teams. These fire-resistant cables ensure a power supply and alarm system operation even during a fire.

Never so fast

The Burj Khalifa’s 57 lifts, produced by world leader Otis Elevator Company, are unlike those in any other skyscraper. Twenty-four of these are machineroom-less elevators (MRL) Gen2 ™, characterised by a refined interior design and cutting edge technology. Two are double-deck observatory elevators, capable of accommodating 21 people on each deck. But most importantly, all the Tower’s elevators go up and down the tower’s 162 floors at record speed: 10m/sec. Prysmian participated in the early stages of the elevator systems electrical wiring planning. Custom elevator traveling and hoistway cables were developed to meet the specific needs of the project. For example, copper/fibre hybrid elevator traveling cables were developed to combine a unique component mix of optical fibre swith multiple shielded communications pairs and power conductors.

“Driving innovation and raising safety standards: this is our constant commitment in helping to build a sustainable future and always supporting ingenuity and vision.”

Project numbers:

162

Fire Proof Floors

57

Cabled elevators

700,000

Fixing accessories

OIL & GAS

Viaggio al centro della Terra con Prysmian Oil & Gas

FAST TRACK PROJECT

Il futuro comincia a Calais, la nostra prima fabbrica 4.0

FT-ETNO SUMMIT 2017

Tracciare la via alla connettività di domani

TELECOMUNICAZIONI

Il nostro impegno a sostegno della banda ultralarga italiana

GRADUATE PROGRAM

Il benvenuto del CEO ai partecipanti a Build the Future

PEOPLE