Work on the worlds longest power cable interconnector linking the UK and Denmark is running on schedule to meet end-2023 delivery despite external challenges including the Covid – 19 pandemic and raw material shortages, said the Prysmian Project Director on Viking link Giuseppe Cardamone.

The Viking Link calls for the design, manufacturing and installation of approximately 1400 kms of cables, 1250 kms submarine cables and 135 kms land cables. More in details, the cables system consists of two poles each one approximately 700 km long installed between the UK converter station located in Bicker Fen, in Lincolnshire, and the landfall located at Houstrup Strand beach, in Denmark.

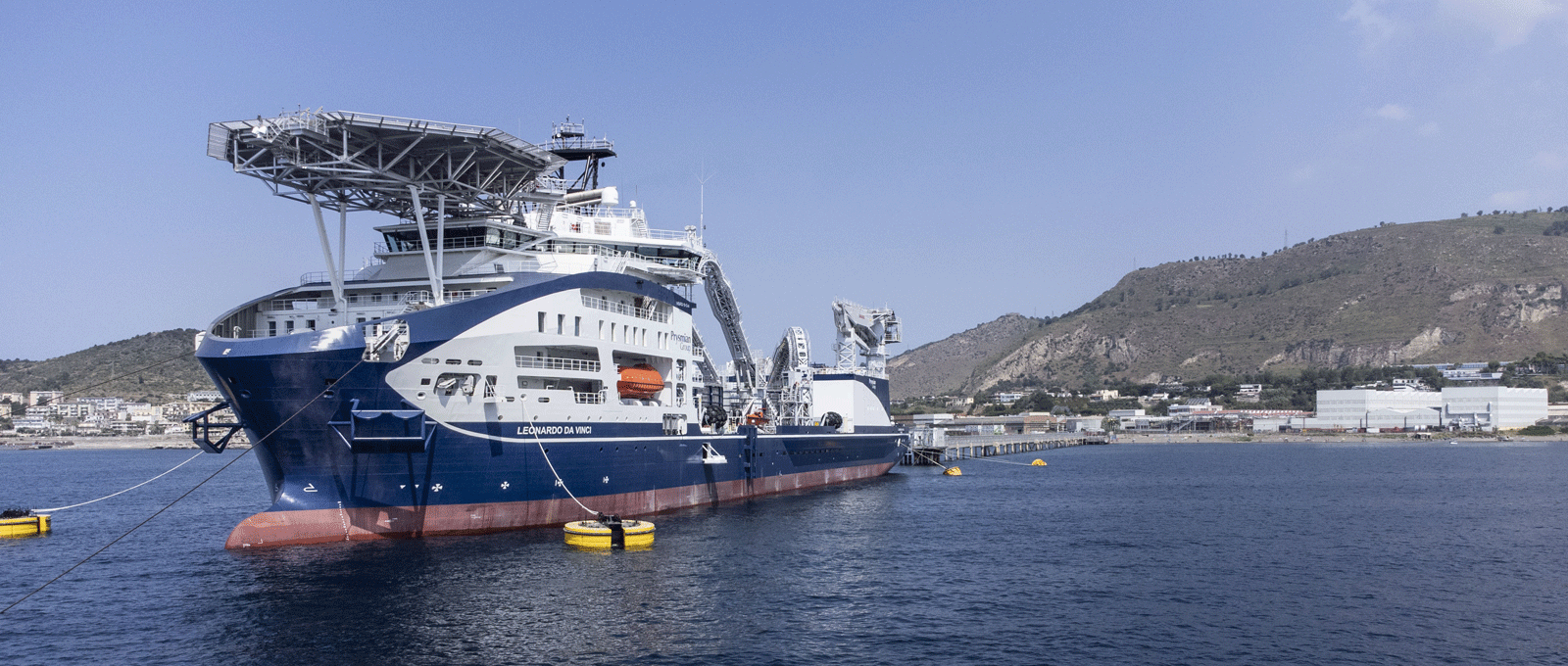

The 1250 km submarine power cables are laid by Prysmian’s cable laying vessels in a bundle configuration. For the first 150 km of the cable route from both UK and Danish shore towards the mid-sea a Prysmian fiber optic cable is laid in bundle together with the two power cables.