Viking Link mega-project will help further improve Arco Felice efficiency

Workers and management at Arco Felice rearrange the factory and adapt production lines for each custom-made project. Viking Link will run for three years and call for all sorts of changes at the plant.

Interconnectors like Viking Link are vital for creating a pan-EU energy market

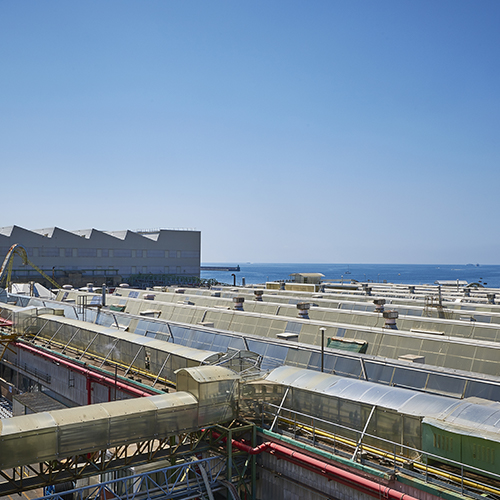

Mario Gallo, Production Manager at the Arco Felice plant near Naples, is accustomed to dealing with the special demands arising from Prysmian’s custom-made submarine cable projects. But for Viking Link he has a rather large problem to solve: where to store a submarine cable that will be 1,250 kilometers long?

Starting in October for the next three years, the factory is committed to producing a €700 million order for an England-to-Denmark interconnector that will be the world’s longest underwater cable. When completed, it will be loaded directly from the seaside plant’s pier to be installed by Prysmian’s new Leonardo da Vinci vessel.

The three-year project will call for all sorts of changes at the plant, Gallo explains. First of all, he will need more storage space. The Leonardo da Vinci will be able to load 13,000 tonnes of cable at a time – double the amount of Prysmian’s other ships but still just a fraction of what will be needed for the Viking Link.

“The Viking project will last three years, and will help us further improve the plant’s efficiency both in terms of materials and manpower,” says Production Manager Mario Gallo. “We may make new investments.”

Each submarine cable produced at Arco Felice is a sort of prototype, requiring the plant’s 20 production lines to be adapted and some of its staff to be re-trained. The factory wrapped up the lapping phase of production of the 950-kilometer North Sea Link cable between the UK and Norway at the beginning of summer. The NSL will be completed in December. The Viking Link mega-project calls for changes in labour practices, organization, and maintenance.

The Viking Link and North Sea Links are the latest examples of how the Group is using its manufacturing excellence at plants like Arco Felice and elsewhere, along with its technical and managerial know-how, to gain a competitive advantage in the growing market for offshore wind power.

“The Viking Link project for nearly €700 million brought the overall value of projects awarded in the first seven months to over €1 billion — the target we had estimated for 2019 full-year,” said CEO Valerio Battista.

Viking Link will enable Denmark, which is aiming to cover half of its electricity needs with wind by 2020, to trade some of its electricity with the UK.

“Viking Link will also help the UK Government meet its carbon reduction commitments by providing access to a well-developed, low cost renewable energy market,” according to the project’s web site.

Viking Link and the North Sea Link are “interconnectors” that allows energy to flow between two different networks. They are important for three reasons. Firstly, they improve security of supply by providing backup if a network fails due to damage or malfunction. Secondly, they can often make energy less expensive, because they can bring power from a cheaper market to a more expensive one. Lastly, the help create a truly single EU energy market. That’s why the European Union refers to interconnectors as “electricity highways,” and funds them with the goal of creating a single energy market. The EU included Viking on its list of PCIs, or “projects of common interest” to build the Priority Corridor Northern Seas Offshore Grid ("NSOG").