Prysmian on time with construction of its Leonardo da Vinci vessel: hull completed and launched

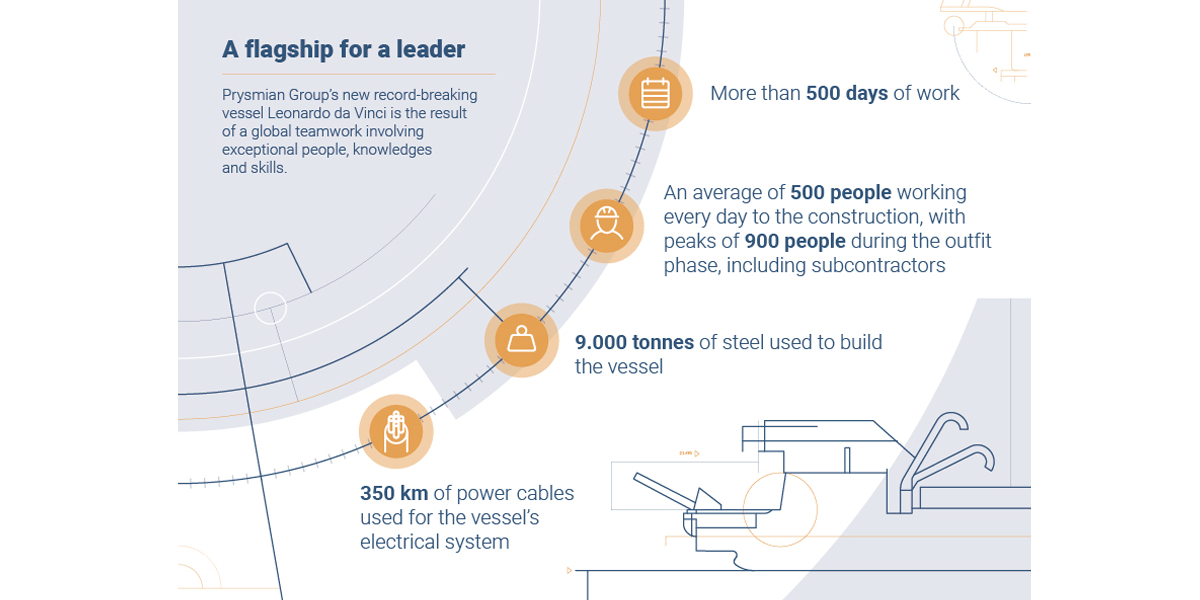

Prysmian Group takes another step forward in the construction of the Leonardo da Vinci, its cutting-edge cable-laying vessel. After completion of all the milestone steps foreseen at Vard’s shipyard in Tulcea, Romania, such as steel cutting, keel laying and installation of main engines, the hull is now fully completed including the entire superstructure and the launching ceremonial — the process of floating the vessel — took place few days ago, perfectly on time with the overall schedule.

The Leonardo da Vinci will be towed to its final destination at Vard’s shipyard in Brattvåg, Norway, for fitting out, installation of main laying equipment (designed, manufactured and supplied directly by Prysmian) and finishing. The journey will take one month of navigation, from the Danube river and across the Mediterranean Sea, to then sail off the ocean coasts of Portugal, Spain and France up to Norway.

“The Leonardo da Vinci will be the most efficient cable-laying vessel in the world and will support the Group’s long-term growth objectives in the submarine cable installation business, strengthening its leadership in the interconnection and offshore wind farm markets. The Leonardo da Vinci is one of our strategic assets: thanks to its unparalleled features, it will support our customers in matching the increasing need for upgrading power grids and in building infrastructures that allow the energy transition to a zero-emission world”

Hakan Ozmen

EVP Projects BU

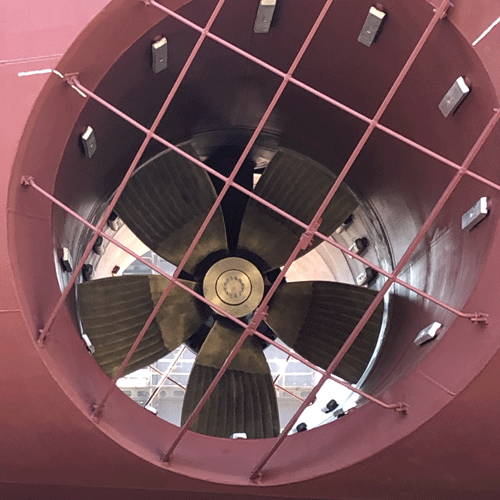

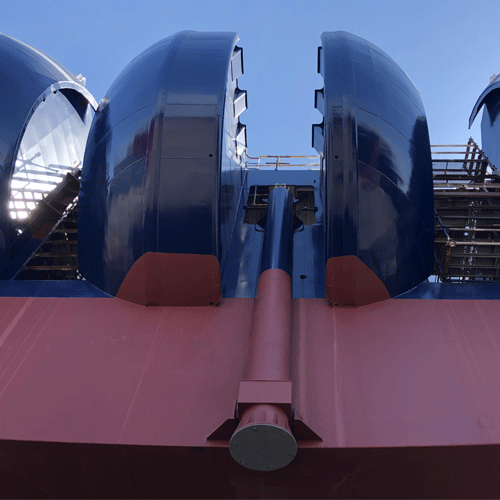

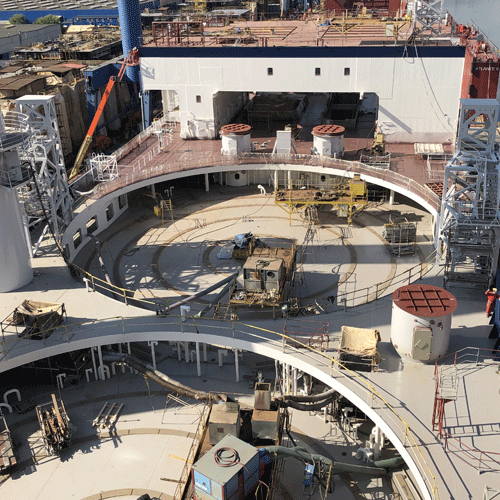

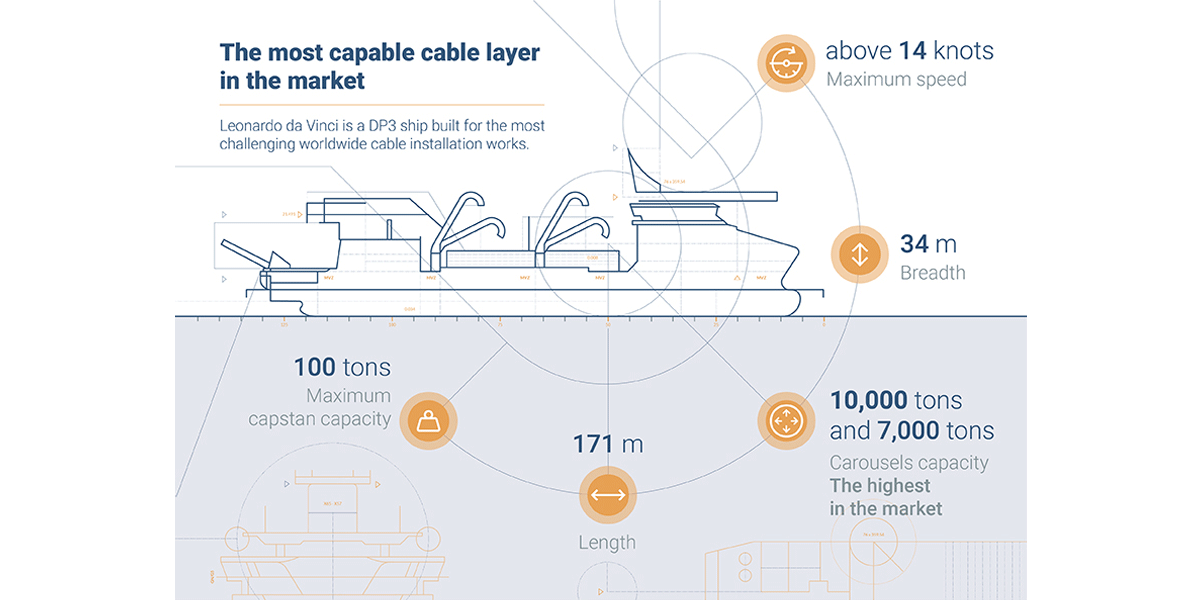

Prysmian is responsible for the design of all cable installation equipment, such as capstan, turntables and their pick-up arms, tensioners. This record-breaking vessel will offer enhanced project flexibility thanks to advanced features like: deep water installation capabilities for depths of more than 3,000 m; 2 carousels of 7,000 and 10,000 tons, which ensure the highest cable loading capacity in the market, enabling an optimized transportation phase from the factories to the installation sites, thus improving overall project efficiency; two independent laying lines to increase its operative flexibility; bollard pull in excess of 180 tons conferring the capability to perform complex installation operations of simultaneous laying and burial, supporting a variety of burial machines like the Heavy Duty Plough and the Hydroplow. In addition, it will be equipped with a state-of-the-art DP3 positioning system, while a specifically designed engine and propulsion set-up will ensure a highly effective seeking capability together with a reduced environmental footprint.

With three of the world’s most advanced cable-laying vessels in its existing fleet — Giulio Verne, Cable Enterprise and Ulisse — and the widest range of high–tech installation and burial equipment, such as the Hydroplows, the HD3 ploughs, the Post Lay Burial machines Sea Mole, SeaRex and Otter, Leonardo da Vinci will consolidate the Group’s leadership in the submarine cables business by insourcing installation activities while achieving on-time delivery and execution.