Developments in wind transmission and Prysmian R&D to enable the energy transition

Electrification and environmental considerations are driving growth in offshore and onshore wind. Srinivas Siripurapu, Prysmian Group’s Chief R&D / Innovation Officer, examines wind farms - fixed and floating - and interconnector trends.

Energy demand is predicted to increase 19% by 2030. At the same time, power generation has to meet increasingly strict carbon neutrality requirements. The Paris Climate Agreement, for example, stipulates that 80% of new electricity generation capacity must come from renewable sources in the coming years.

That means that Transmission System operators (TSOs) will need to integrate vast amounts of energy from renewable sources. Distribution System Operators (DSOs) also need to accommodate more renewable energy sources and meet demand driven by electrification. Grids will have to guarantee consistent performance and accommodate local wind and solar energy production.

But where will ‘green’ energy primarily come from? Hydrogen is an interesting option to address heavy carbon intensive industries such as Chemicals and Aviation. However, we are at least a decade away from scalable hydrogen systems. What’s more, Hydrogen is the smallest molecule in the periodic table and care has to be taken to have safe & reliable infrastructure. Of course, Hydrogen-based electrolysers will also need cabling and power.

Offshore wind is a highly promising option, that offers us a fighting chance of reaching the Paris Climate Accord targets. We should see 200GW of additional offshore wind capacity appearing in the next ten years. Also starting 2026 we expect floating windfarms to pick up scale and become more widespread.

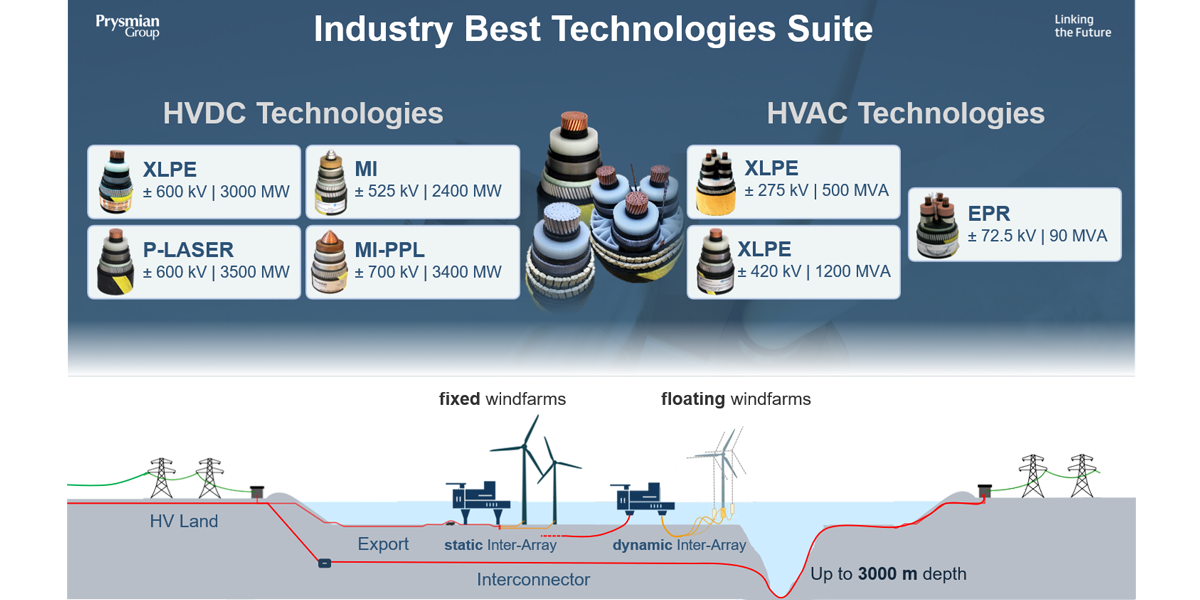

In a typical offshore windfarm, each wind turbine generates up to 20MW of AC power which is transmitted to AC substations via inter-array cables. From there, export cables run to a DC converter station on land. These export cables can be AC or DC, depending on the overall system design (to reduce losses, cables over 100 km in length are preferably DC). From the DC converter station, overhead or underground high voltage lines transmit power inland. What challenges does this introduce?

First of all, we need to push more power to – typically – Transmission System Operators, who are risk adverse and have very high-quality expectations. Then there’s more pressure on overall system cost. This is directly linked to the drive to reduce the levelized cost of electricity from renewables required for complete decarbonisation.

Prysmian is the market leader, thanks to our know-how, our experience over several decades and the array of technologies we offer covering both mineral insulated (MI and MI-PPL) and extruded (XLPE and P-Laser) cable systems. Over the past ten years, interconnectors have been the largest part of our high voltage cable business. However, certain drivers, such as environmental considerations and the race to net zero will very significantly drive up the proportion of the offshore wind sector.

There’s also a clear demand for sustainability driven innovations that supports company’s CSR goals. For example: elimination of lead that has historically been used to provide water tightness in submarine cables and finding viable alternatives to SF6 gas (the most potent greenhouse gas per Kyoto protocol) currently in use for high voltage cable and accessories testing. In addition, a key innovation that will find more opportunities in the near future is our high depth submarine cable design that replaces steel armour with synthetic Kevlar armour. We can now deploy submarine cables at record depths up to 3000m such as in the Mediterranean Sea.

P-Laser: faster operations, higher performance, more sustainable

P-Laser technology – a breakthrough high performance thermoplastic recyclable cable, permits a more efficient cable production with lower carbon footprint than traditional cross-linked polyethylene. The advanced design of 525kV HVDC P-Laser can push over 2GW of power per cable lowering the environmental impact for interconnectors such as the German HVDC Power Transmission projects. Further today interconnectors require bidirectional flow of power to increase flexibility in the energy markets. P-Laser has been developed to address two more performance improvements in terms of polarity reversal and a higher operating temperature compared to traditional HVDC systems. In additional P-Laser is compliant with a full circular economy. In short, P-Laser is a win-win-win for operations, product performance and the environment.

Innovation ambition

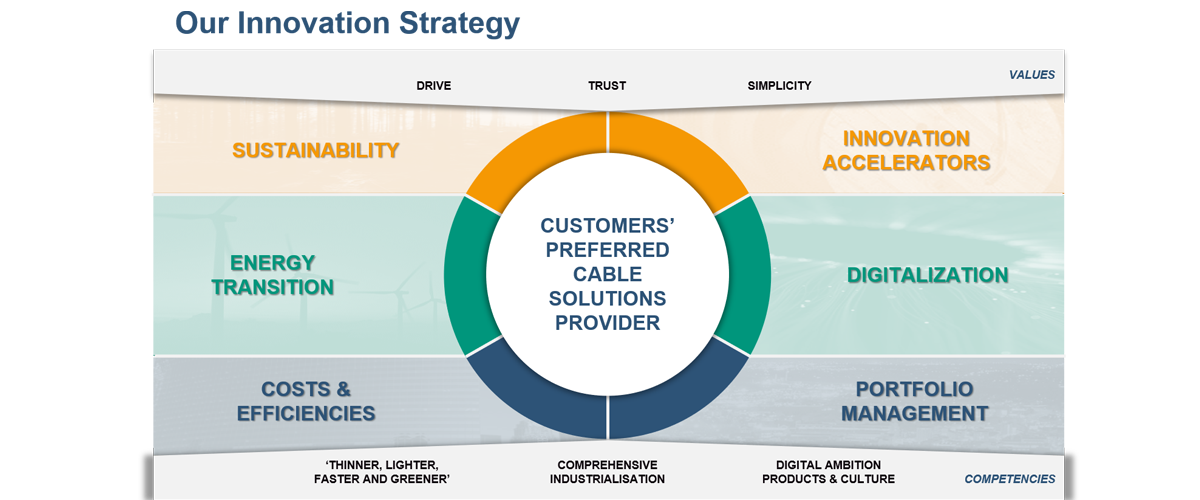

Prysmian wants to be our customers preferred cable solutions provider, so we’re focused on full systems. Cables, accessories, sensors, monitoring and installation services. Our innovation strategy focuses on creating maximum added value from products and services.

We have the most extensive product portfolio and geographical footprint to address the needs of our customers anywhere in the globe. Our R&D teams play a vital role to continuously optimize our product costs and manage the portfolio to service our customers with speed and reliability. Portfolio management is key to eliminate complexity and delight our customers.

For longer term growth, we are increasing our R&D efforts on sustainability to support our climate change ambition to be net zero on scope 1&2 emissions by 2035 and scope 3 by 2050. To realise this, our mantra when developing new products is: 'Thinner, Lighter, Faster, Greener'.

Through Corporate Hangar our external innovation accelerator, we work in an open innovation model to identify adjacencies to our current portfolio to benefit our customers. The key is to get the right voice of the customer and understand their current pain points for example ease of installation or ability to track our cable drums.

As the market leader, we have to be equally good on all three fronts: customer proximity and service levels, cost management, and innovation leadership. Product quality is, of course, a given. So we are developing new competencies that will help us do exactly that. For example, our digital innovation team is developing new digital products, introducing predictive intelligence and improving the digital culture of our company.

We spend more than 100M€ annually on R&D & innovation and there are some 950 employees at Prysmian R&D, 750 of which are scientists and engineers. We have every area of study in house, from chemical, mechanical and electrical engineering to physics and metallurgy. We have innovation teams for materials, technology, and product design as well as labs – the kind of testing we require is not something that you can get done anywhere. We also have specialized expertise in extra high voltage and submarine testing. My main commitment is to encourage our engineers to take risks while following a disciplined and scientific approach to new products both development and industrialization. Of course, learning from failures is also key to innovation!

Srinivas Siripurapu, Chief R&D Officer and Chief Innovation Officer at Prysmian Group, has a background in the chemical, engineered materials and cabling industries. His responsibilities include ensuring that Prysmian has the right innovation talent pipeline with the right technical depth and expertise, ensuring R&D is aligned with business strategy, cost management, and new product commercialisation. ‘Srini’ has a PhD in Chemical Engineering from North Carolina State University. He is passionate about sustainability, materials science and mentoring young engineers. He is a certified Lean Six Sigma Black Belt and is an inventor on over 50 patents.

Prysmian white paper: “Enabling the energy transition: Why cable technologies are essential for more efficient and sustainable power grids.”

Slowing global warming, largely through decarbonization, is urgent. The required transition to renewable energy is strongly linked to the capability to transmit energy from where clean energy is produced to where it is consumed. A vastly increased level of wind power needs to be accommodated, along with increased (international) underground and subsea transmission, distribution, interconnections and grid optimization requirements. Cables, including installation and maintenance, are crucial to all key projects supporting the energy transition. Prysmian is fully committed to leverage its knowledge and solutions to accelerate a decarbonized future energy system and ultimately help protect the climate.

Our new whitepaper look at the status and economic aspects of the energy transition, and the role of power grids in enabling a net-zero energy system. Social transformation, and the energy transition. The whitepaper also summarises how Prysmian is supporting a fossil-free future, and which skills and resources are vital to this.