Unmatched capabilities to deliver for Russia’s largest LNG plant

On completion, this truly ambitious project will double Russia’s current export capabilities.

A project on a grand scale

At Sabetta, north east of the Russian Yamal Peninsula, extensive work was required on a new liquefied natural gas plant called Yamal LNG.

Drawing largely on the Yuzhno-Tambeyskoye gas field, by 2021 it will be producing a staggering output of around 16.5 million tonnes of liquid natural gas per year.

In support of this, a considerable infrastructure has been developed. An infrastructure that includes three fully operative trains for gas transportation and a specially constructed seaport, airport and power plant.

The power plant, built by Technopromexport, will field eight industrial gas turbines, allowing a capacity of 282 MW.

Multiple partners with a range of needs

This complex project has seen the involvement of multiple Engineering, Procurement and Construction (EPC) contractors to develop field infrastructure onsite, each with different cable requirements.

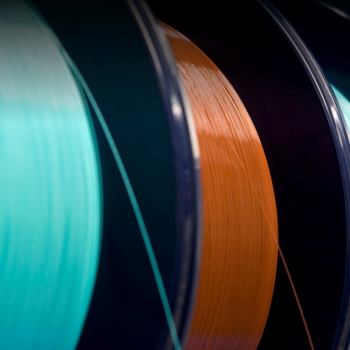

In recognition of our broad portfolio of technologically superior cable solutions for the Oil & Gas market, Prysmian was awarded a number of contracts spanning pipeline, LNG and storage applications. Initially, we were awarded a contract for 28 km of high-voltage cables (110 kV) by the Yamgaz consortium (which includes Technip among others) which designed and commissioned the plant.

Additionally, our wide product portfolio meant we were engaged by other notable EPCs to supply Medium Voltage cables, Low Voltage cables, and Control and Instrumentation cables for modularised buildings on site.

Keeping our cool in extreme conditions

Not only could we provide the full spectrum of cables needed by the various EPCs involved in the project, we could also deliver reliable, cost-effective performance for all of our products in even the harshest conditions.

With temperatures in Siberia often plummeting to -40°C, we ensured every cable we supplied featured our ‘Arctic Onshore’ low temperature technology and was fully certified according to GOST standards and technical specifications.

This means the cables could be installed in freezing conditions and the plant can continue to function at optimum levels even at very low temperatures, minimising the risk of costly downtime.

Flexible designs, tailored by request

Due to our operational flexibility and expertise in the sector, we were able to further tailor our cable offering according to the specific needs of the customer. For example, we conducted impulse tests on our High Voltage and Medium Voltage cables, successfully exposing them to temperatures as low as -50 °C to ensure optimal functioning.

Similarly, with the High Voltage cables required, we were able to take the specifications of the project into account and designed them to be installed in air, lying on flat racks. A clever adaptation of a typical installation solution for oil plants, not normally used for HV links that we knew would help enhance the performance of the HV circuit.

An extended operational footprint

Finally, it’s our ability to deliver multiple products to multiple suppliers in remote locations such as Yamal that is a key strength. Indeed we are almost unique in our ability to cater to a project of this size.

Thanks to our broad customer base, we’ve developed a strong capillary presence in the territories meaning we were able to co-ordinate the manufacture of the cables at our different international locations and successfully deliver them to the various EPCs in time for installation. A feat that would simply be beyond other companies.

Where did our cables come from?

For Yamal, our Medium Voltage cables were manufactured in Turkey, our High Voltage cables in Italy. Our Low Voltage, Control and Instrumentation cables in Spain and Singapore.

A global, innovative and flexible company

Put simply, our success for this eminent project confirms our position as a key supplier of advanced performance cable systems. Not only can we add value with our broad industrial and commercial footprint, but our flexibility and capacity to adapt to individual requirements makes us the number one choice for ventures in the Oil & Gas sector.

MAKE IT PROGRAM

Make It: Good people make great companies

CORPORATE

Staying the course, in the UK

FAST TRACK PROJECT

The future starts in Calais, Prysmian’s first 4.0 factory

FT-ETNO SUMMIT 2017

Debating the connectivity of tomorrow

GRADUATE PROGRAM

Prysmian Group CEO welcomes 50 young hired

PEOPLE